In the complicated machines that run many industries, simple but important parts called shafts and keys are very important for moving power and keeping the machine’s purity. These parts are what hold spinning systems together and make sure they work well and reliably.

Let’s go through the wide world of shafts and keys, looking at the different kinds of them and how they’re used in everyday machines.

Shafts: The Rotational Backbone

A shaft is a cylindrical rod that transmits rotational motion or torque from one part of a machine to another. It serves as the axis of rotation for gears, pulleys, and other components.

Types of Shafts

- Straight Shaft: The most common type, a straight shaft, is a simple, unaltered cylindrical rod. It’s straightforward in design and finds application in various machinery.

- Stepped Shaft: A stepped shaft has sections of varying diameters, allowing for different components or bearings to be mounted at distinct points along its length.

- Splined Shaft: Featuring longitudinal grooves or ridges (splines) along its length, a splined shaft enables the connection of other components with matching splines, providing a secure and precise fit.

- Flexible Shaft: Unlike rigid shafts, flexible shafts are capable of bending or curving, making them suitable for applications where a direct line of sight is challenging.

- Hollow Shaft: A hollow shaft, which has a central void, is advantageous in weight-sensitive applications because it is lighter than its solid counterpart without sacrificing strength.

Keys: Ensuring Synchronized Rotation

Keys are small, yet crucial, components used to connect a shaft to other rotating elements like gears, pulleys, or wheels, preventing slippage and ensuring synchronized rotation.

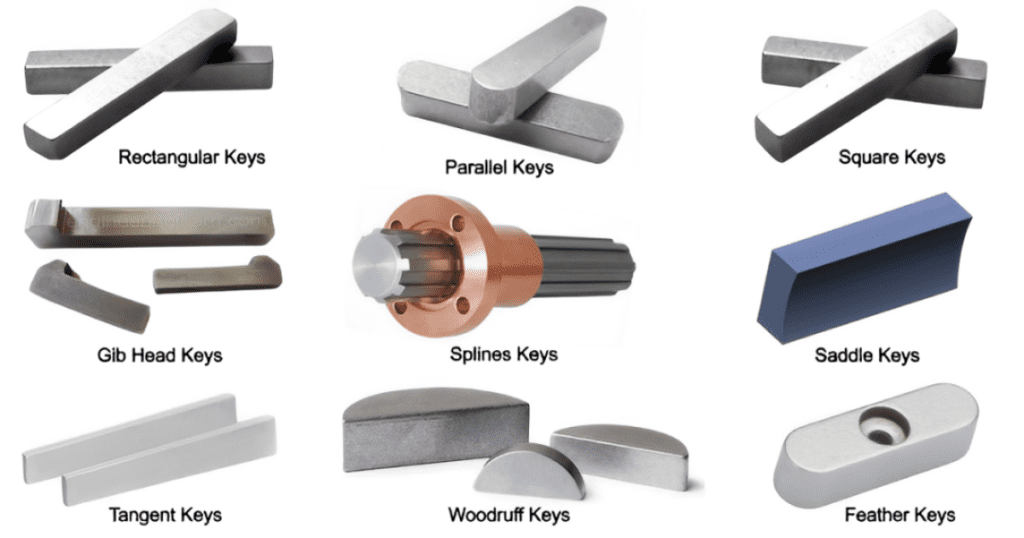

Types of Keys

- Rectangular Key: The most common type, rectangular keys have a straightforward design with a rectangular cross-section. They are easy to manufacture and suitable for transmitting moderate torque.

- Square Key: Similar to rectangular keys but with a square cross-section, these keys provide more surface area for torque transmission, making them suitable for heavier loads.

- Woodruff Key: Designed for use in narrow keyways, the Woodruff key has a half-moon shape, allowing it to fit into a semi-circular groove in the shaft.

- Tapered Key: Tapered keys have a wedge-like shape, providing a secure fit in tapered keyways. This design enhances the key’s ability to withstand shear forces.

- Gib Head Key: This type of key features a larger head on one end, making it easier to install and remove. The gib head provides additional surface area for force distribution.

- Saddle Key (Half Moon Key): Resembling a half-moon, the saddle key fits into a corresponding groove in the shaft and the component, preventing rotation.

- Round Key: Circular in cross-section, round keys are often used in rotating shafts where a torque requirement is moderate and precision is not critical.

Conclusion

In the complex web of machinery, the way shafts and keys work together is like a well-choreographed dance—they transfer power smoothly and make sure that all the parts rotate at the same time. Straight shafts are simple, splined shafts are flexible, and keys come in a lot of different styles. These parts are the unsung stars that make a lot of machines work well.

As we learn more about spinning systems, it becomes clear how important it is to know the different kinds of shafts and keys and how they are used. This shows how important they are to the machines that run our modern world.

To further expand your knowledge in the realm of Shafts and Keys, please watch the video below explaining Keyseats and Keyways.