Electric motors, which are the silent engines that keep our modern world running, are found in many of the tools we use every day. From the spinning blades of a ceiling fan to the powerful motors that move an electric car, these engineering marvels turn electricity into mechanical motion very efficiently.

Have you ever thought about what’s beneath the sleek outer appearance—the intricate system of parts that makes this change possible?

Let’s explore and learn about the key elements that drive electric motors and how an electric motor works.

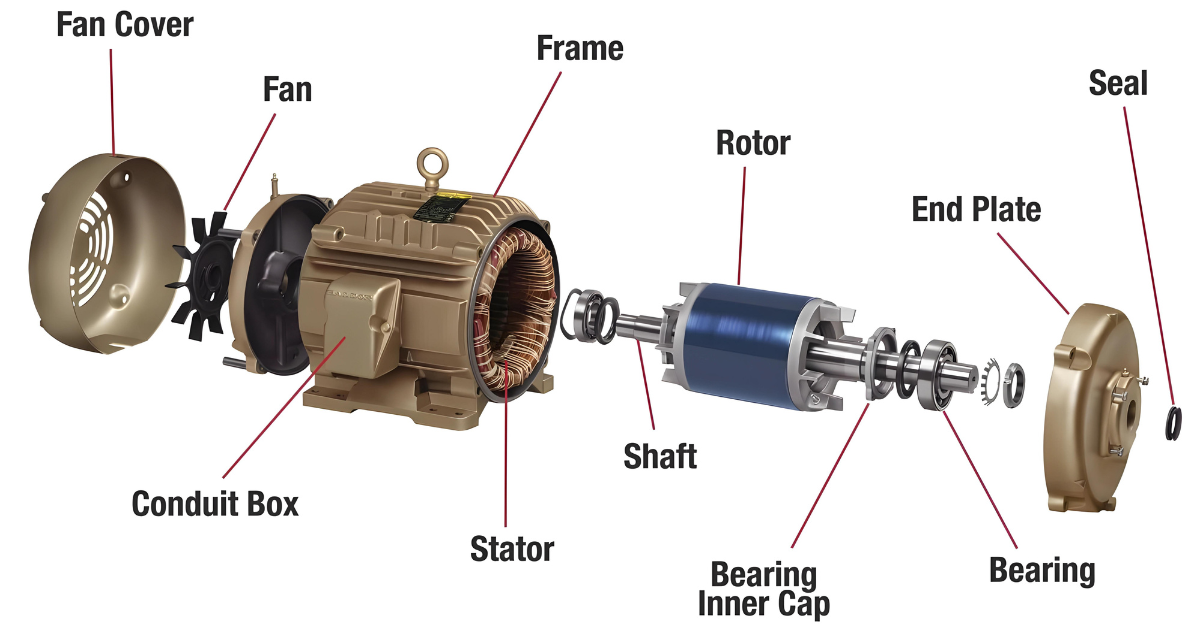

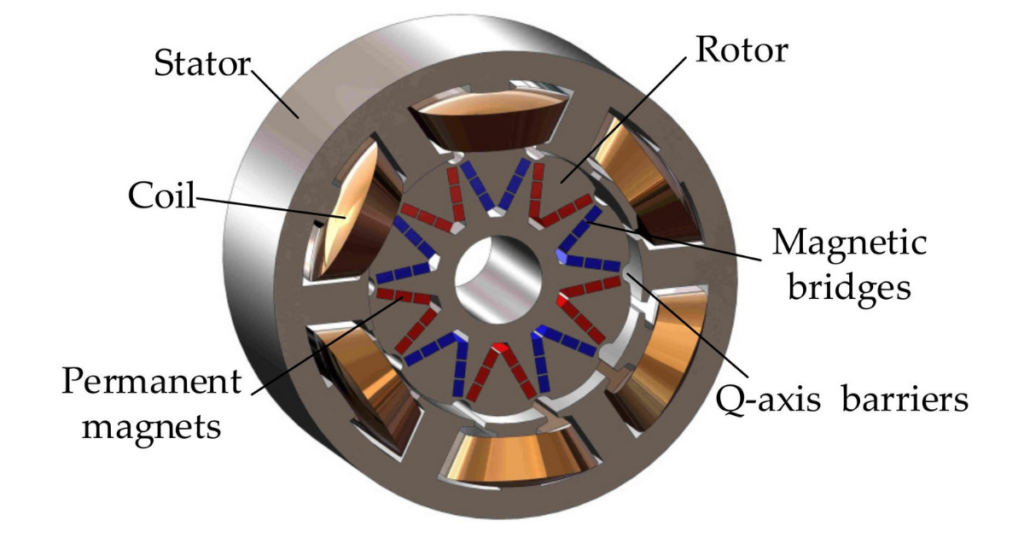

Stator

At the heart of every electric motor lies the stator, an immovable component that generates a magnetic field when an electric current passes through it. Typically constructed with laminated iron cores to minimize energy losses, the stator serves as the foundation upon which the motor’s functionality relies.

Rotor

The counterpart to the stator, the rotor, is the moving component within the electric motor. The rotor also referred to as the armature, rotates within the magnetic field that the stator produces. This interaction creates a force that drives the rotation of the rotor, thereby producing mechanical motion.

Windings

The stator and rotor both contain windings and coils of wire that play a pivotal role in the motor’s operation. In the stator, the windings receive the electrical current, creating a magnetic field. Meanwhile, the rotor’s windings interact with this magnetic field, resulting in the rotational movement of the rotor.

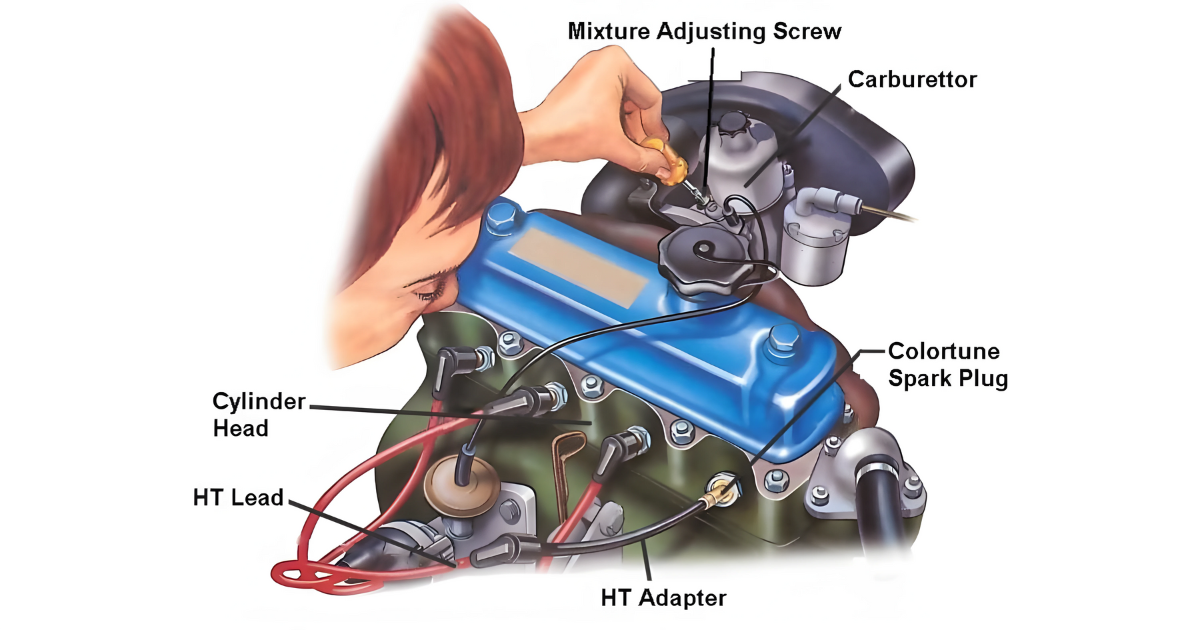

Commutator

In direct current (DC) motors, the commutator is a critical component responsible for reversing the direction of the electric current in the rotor windings. This reversal ensures a continuous rotation of the rotor, which is essential for the sustained motion of the motor.

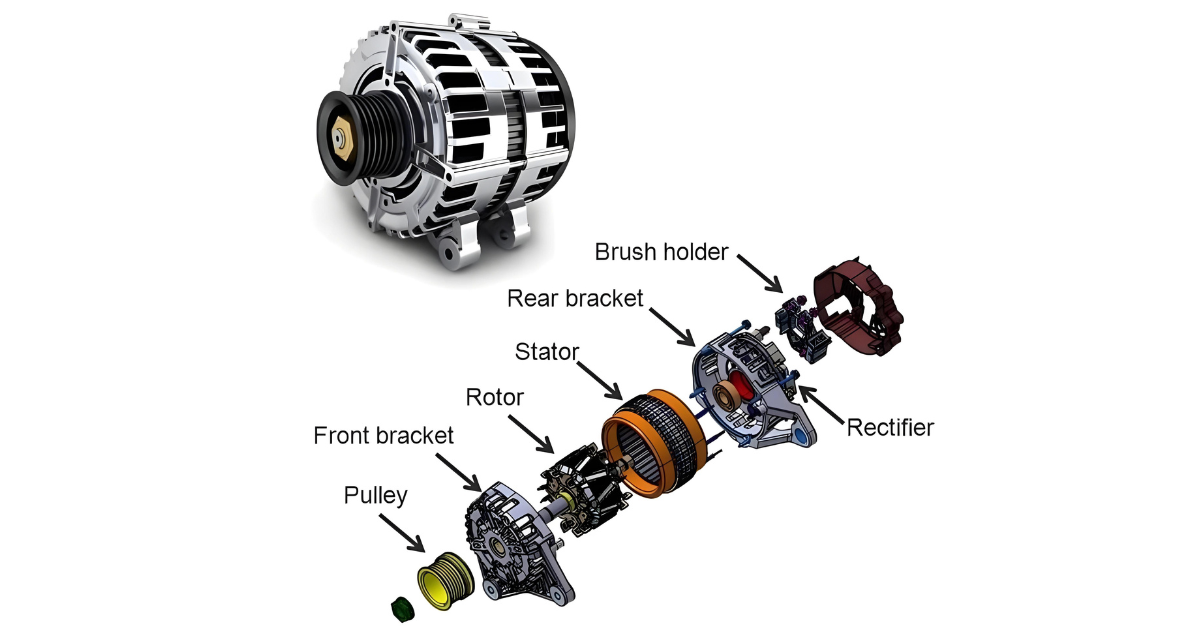

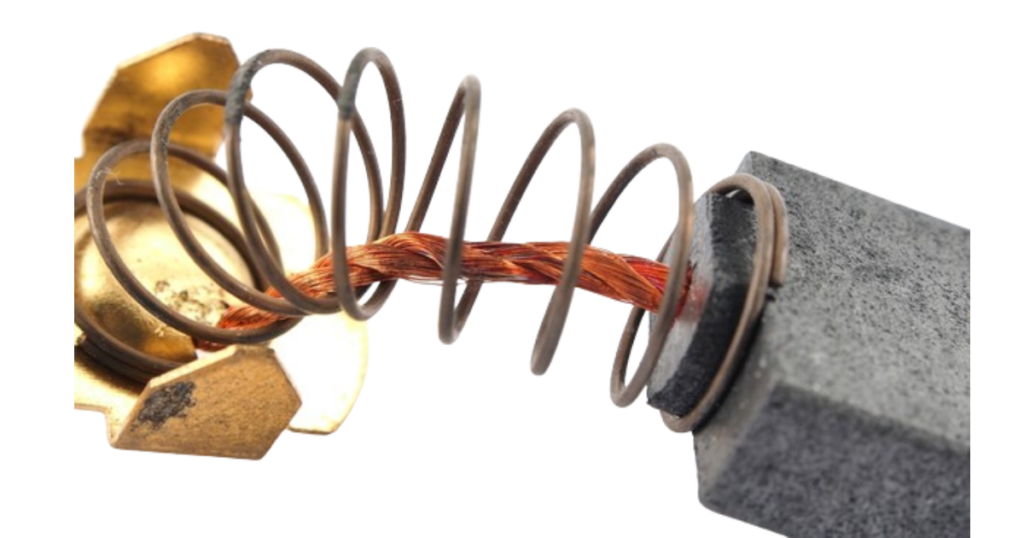

Brushes

Commonly found in brushed DC motors, brushes are conductive components that maintain electrical contact with the commutator. The brushes enable the transfer of electric current to the rotor windings, facilitating the continuous rotation of the rotor within the magnetic field.

Bearings

To ensure smooth and efficient rotation, electric motors are equipped with bearings. These components reduce friction between moving parts, providing support for the rotor’s shaft. High-quality bearings contribute to the motor’s longevity and overall performance.

Housing

The housing or frame encapsulates the entire motor assembly, providing structural support and protection for the internal components. It is typically constructed from materials such as aluminum or steel, offering durability while efficiently dissipating heat generated during operation.

Magnets

Permanent magnets or electromagnets, are often incorporated into the design of electric motors. In brushless DC motors, for example, magnets on the rotor create a magnetic field that interacts with the stator’s windings, eliminating the need for a commutator and brushes. This design enhances efficiency and reduces maintenance requirements.

Enclosure

For electric motors operating in diverse environments, an enclosure is crucial for safeguarding the internal components from external elements like dust, moisture, or contaminants. The type of enclosure varies based on the specific application and environmental conditions.

Capacitors

In certain alternating current (AC) motors, capacitors are employed to enhance the motor’s performance. Capacitor-start motors, for example, utilize a capacitor to provide an additional phase shift, promoting efficient starting and smoother operation.

How Does an Electric Motor Work?

An electric motor works like magic to turn electricity into movement. Here’s a simple breakdown:

- Electricity Flows In:

- When you switch on the motor, electricity flows into it.

- Creating a Magnetic Field:

- Inside the motor, there’s a part called the stator. It loves electricity and turns it into a powerful magnetic field.

- Rotor Gets in the Game:

- Now, there’s another part called the rotor. It’s attracted to the magnetic field and wants to play with it.

- Spinning Action Starts:

- The rotor starts spinning because it’s attracted to and wants to follow the magnetic field created by the stator.

- Keep the Flow Going:

- To keep the spinning going, some motors have brushes and a commutator. They help the electricity flow in the right direction, keeping the rotor happily spinning.

- Or Go Brushless:

- Some motors are smart and go “brushless.” They use magnets and electronics to keep the spinning smooth without brushes.

- Making Things Move:

- Once the rotor is spinning, we connect it to something useful, like wheels in a car, a fan, or anything else we want to move.

- Voila! Movement Happens:

- And there you have it—electricity turns into a magnetic dance, making things move with the help of the electric motor. It’s like a cool science dance party inside the motor!

To get a visual understanding of how an electric motor works, please watch the video below.

Conclusion

Electrical motors are complicated machines with many parts that work together to turn electrical energy into mechanical motion. Every part of the motor, from the static stator to the dynamic rotor, is very important to its efficiency.

As technology improves, new materials and designs are used to make electric motor parts better and more efficient. This leads to more electric power options that are long-lasting and environmentally friendly.