Within the complex network of mechanical systems, there exists an often overlooked yet vital component that silently carries out the important duty of transferring power with precision and effectiveness. The bevel gear is a basic component that is essential for redirecting rotational motion. Its unique conical shape makes it easily recognizable.

Let’s explore the fascinating world of bevel gears, where we’ll uncover their design, applications, and how they enable precise motion in different industries.

Bevel Gears

Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts. Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics.

Types of Bevel Gears

- Straight Bevel Gears: In their simplest form, straight bevel gears have straight teeth and intersect at the apex of the cone. They are widely used in applications where simplicity and cost-effectiveness are key considerations.

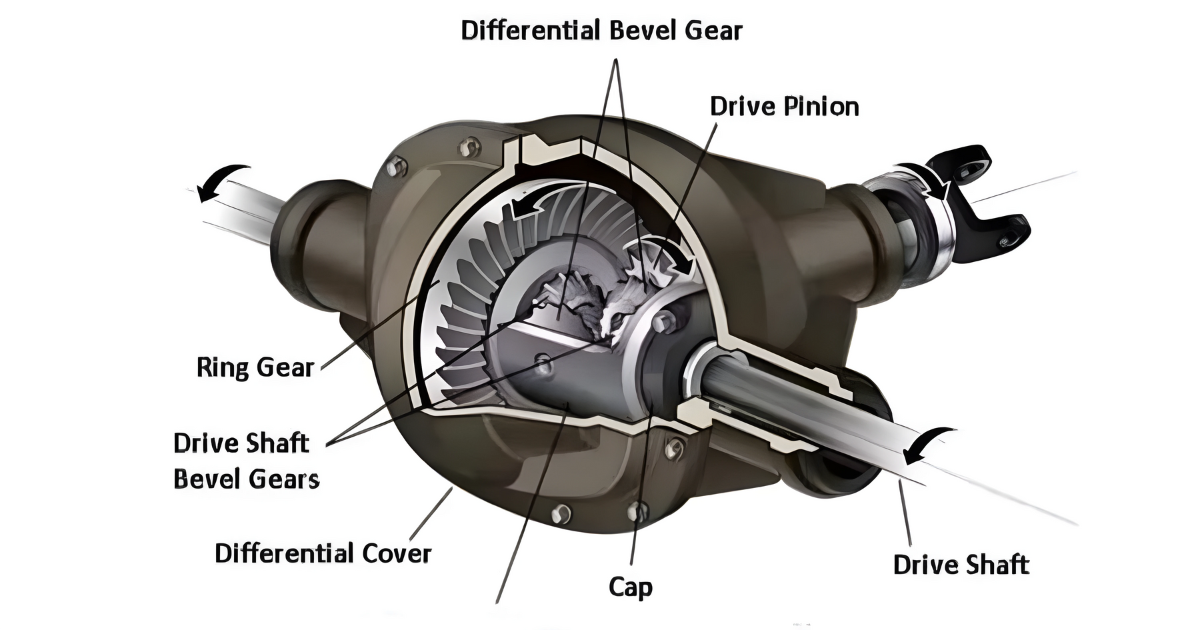

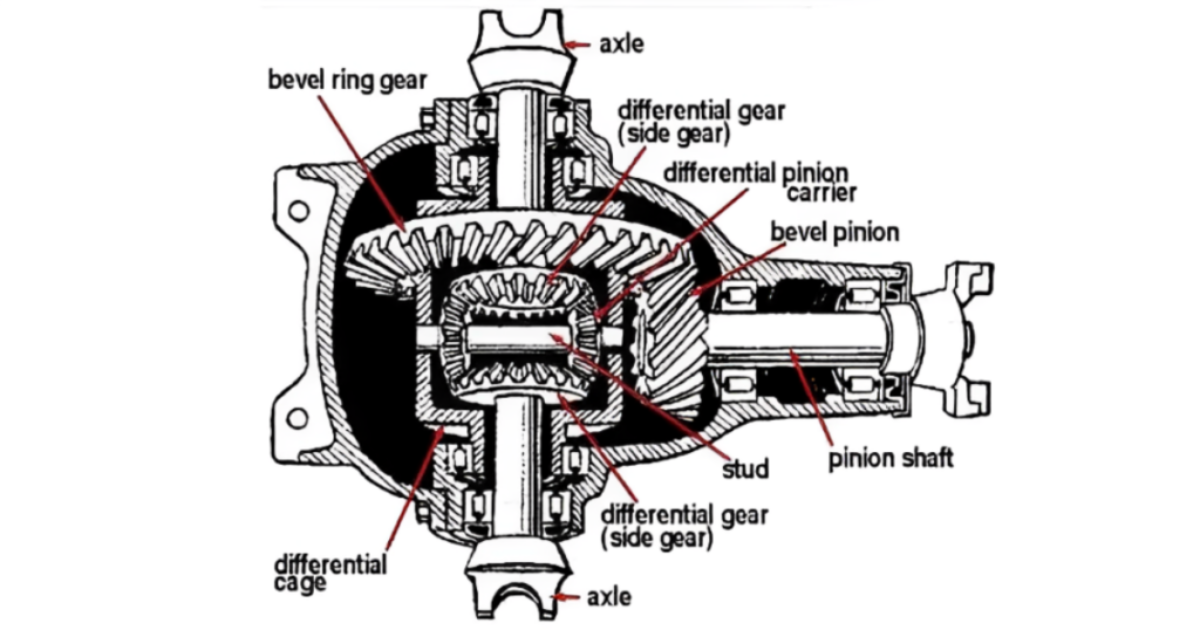

- Spiral Bevel Gears: Spiral bevel gears feature curved teeth that spiral around the cone. This design reduces noise and vibration, providing smoother operation. Spiral bevel gears are commonly found in automotive differentials.

- Hypoid Gears: Similar to spiral bevel gears, hypoid gears have offset axes, allowing for smoother meshing and greater flexibility in design. They are often used in applications where shafts need to intersect at a non-right angle.

Meshing Mechanics

- Intersecting Axes: Bevel gears are designed to mesh with each other when their shafts intersect. The meshing process involves the engagement of the gear teeth, facilitating the transfer of rotational motion from one shaft to another.

- Angular Velocity: The angled teeth of bevel gears contribute to a changing angular velocity as they rotate, allowing for smooth motion transmission even when the intersecting shafts are not parallel.

Applications in Industry

- Automotive Systems: Bevel gears find extensive use in automotive applications, particularly in the differential mechanism. The differential uses bevel gears to transmit power from the drive shaft to the wheels while allowing them to rotate at different speeds during turns.

- Aerospace Industry: Bevel gears are employed in various components of aircraft, such as landing gear systems and helicopter rotors. Their ability to transmit power at non-right angles makes them valuable in aerospace engineering.

- Power Tools: Bevel gears are commonly used in power tools like drills and saws. Their efficient power transmission and ability to redirect motion at different angles contribute to the versatility of these tools.

- Marine Propulsion Systems: Bevel gears play a crucial role in marine propulsion systems, enabling the transfer of power from the engine to the propeller shaft. Their durability and efficiency are vital in the demanding conditions of marine environments.

Advantages of Bevel Gears

- Compact Design: Bevel gears offer a compact and space-efficient solution for redirecting rotational motion, making them suitable for applications with limited space constraints.

- Efficient Power Transmission: The meshing of bevel gears results in efficient power transmission, minimizing energy losses, and ensuring smooth operation.

- Versatility in Design: The versatility of bevel gears allows engineers to tailor their design to specific requirements, choosing between straight, spiral, or hypoid configurations based on the application’s needs.

Challenges and Considerations

- Axial Thrust: Bevel gears may generate axial thrust due to the offset nature of their teeth. This thrust needs to be carefully managed, often requiring additional bearings or thrust washers in the system.

- Complex Manufacturing: The manufacturing of bevel gears, especially spiral and hypoid gears, can be more complex than that of straight gears. Precision is crucial to ensuring proper meshing and performance.

Maintenance and Lubrication

- Regular Inspection: Regular inspection of bevel gears is essential to identify signs of wear, misalignment, or damage. Timely maintenance can prevent issues and extend the lifespan of the gears.

- Lubrication: Proper lubrication is crucial for the smooth operation of bevel gears. Lubricants reduce friction, dissipate heat, and protect against wear, ensuring the gears function optimally.

Conclusion

Bevel gears, known for their elegant conical design, play a crucial role in transmitting motion across different industries. Their versatility and efficiency make them essential in various machinery applications, from automotive differentials to aerospace.

With the constant progress of technology, bevel gears remain at the forefront of innovation, constantly adapting to changing needs and pushing the limits of what can be achieved.

For a visual explanation of bevel gears and their operation, check out the video below.