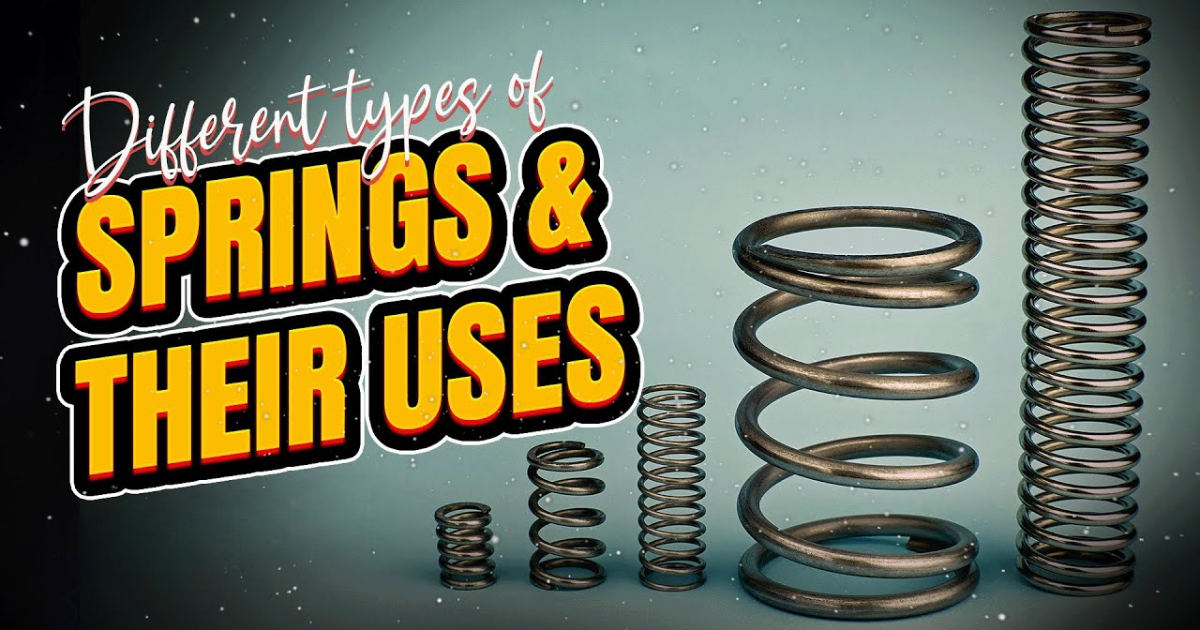

Springs are simple but very useful mechanical parts that are used all the time in our daily lives and in many industries. They do a lot of quiet work, from supporting our beds to playing important roles in machines and cars. Because they can store and release energy, they are very useful in many situations.

We will talk about the wide world of springs, including the different kinds and what makes them special.

Compression Spring

Common compression springs are simple, storing energy when compressed, releasing it when force is removed. Used in pens, mattresses, and car suspensions, they resist axial pressure.

Extension Spring

Extension springs lengthen when pulled, releasing stored energy upon force release. Widely used in garage doors, trampolines, and industrial applications, they provide flexibility and a dependable return force.

Torsion Spring

Torsion springs operate by twisting around an axis, storing energy with applied torque and releasing it upon torque release. Widely used in doors, lids, and various mechanical systems for their ability to exert rotary force.

Constant Force Spring

Constant force springs are frequently in the form of a tightly wound coil and exhibit a nearly constant force throughout their deflection. They are used in tape measures, window counterbalances, ensuring consistent force.

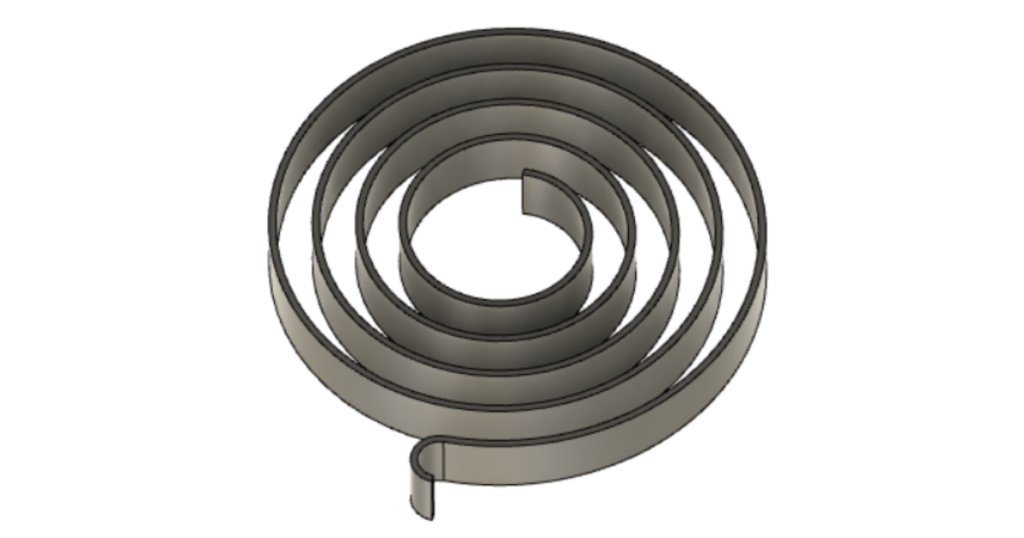

Clock Spring

Clock springs are tightly wound coils often used in applications where rotational force is required. They find their place in retractable cords, reel-type devices, and, as the name suggests, clock mechanisms.

Belleville Spring (Disc Spring)

Belleville springs are conical-shaped discs that, when stacked together, provide a high spring rate in a compact space. Ideally used in bolted joints, providing dynamic solutions for high-load applications with minimal deflection.

Garter Spring

Garter springs, also known as constant force springs, offer consistent force throughout their deflection. Commonly seen in retractable tape measures and window counterbalances, they provide reliable and constant force.

Spring Belt

Utilizing the concept of a tightly wound coil, spring belts offer flexibility in applications where rotational force is required. They find use in retractable cords, reel-type devices, and clock mechanisms.

Magazine Spring

Found in firearms, magazine springs provide the force needed to feed ammunition into the firearm’s chamber. Their reliability is crucial for consistent and controlled ammunition feeding.

Conical Spring

Conical springs, with a tapered shape, offer varying spring rates within the same spring. This design is advantageous in applications where a progressive force is required.

Concave Spring

Concave springs, with a curved or inward shape, are designed to provide flexibility and support in applications like seating arrangements or cushioning systems.

Volute Spring

Volute springs, with a spiral or coiled shape, are often used in applications requiring a strong yet compact spring. Their design allows for efficient energy storage and release.

Barrel Spring

Barrel springs, named for their barrel-like shape, provide a combination of compression and torsion forces. This design is beneficial in applications where space is limited.

Variable Pitch Spring

Variable pitch springs have a varying pitch along their length, allowing for different spring rates in a single spring. This design provides versatility in managing varying loads.

Wave Spring

Wave springs, with a distinctive wave-like design, offer a compact and lightweight alternative to traditional coil springs. They find application in tight spaces where axial space is limited, such as in bearing preload, seals, and connectors.

Gas Spring

Gas springs utilize compressed gas to provide a controlled and smooth lifting or lowering force. Often used in automotive applications for trunk lids and hoods, gas springs offer adjustable and consistent support.

Die Spring

Die springs are heavy-duty compression springs primarily used in high-stress applications, such as in metal stamping dies. Their robust design allows them to withstand heavy loads and provide reliable and consistent force.

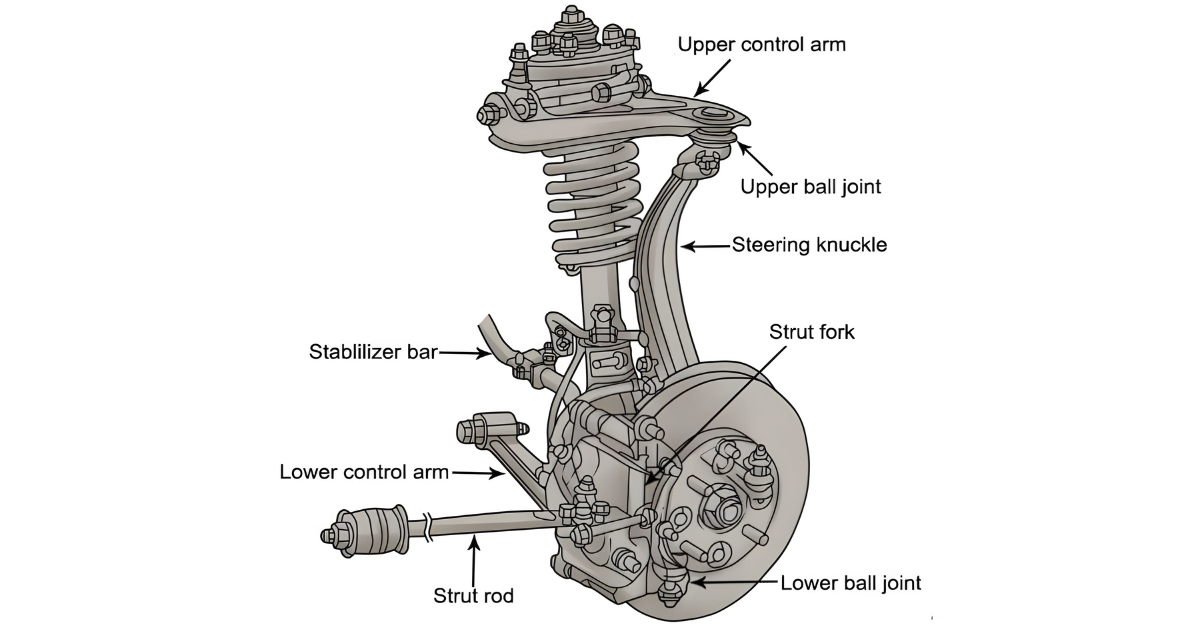

Leaf Spring

Commonly found in automotive suspensions, leaf springs consist of multiple layers of flat steel strips bound together. They offer support and flexibility, distributing weight and providing a smooth ride.

Conclusion

From basic coil springs to intricate garter and variable pitch springs, each type has unique qualities. Understanding these springs is not just fascinating but essential for selecting the right one, ensuring optimal performance and reliability in various mechanical systems. As technology advances, new spring designs continually push the limits of these seemingly simple yet crucial components.