Engine valves play a pivotal role as conductors in the mechanical symphony that is the heart of internal combustion engines. In controlling the air and exhaust gas flows, which dictate the combustion rhythm, these little parts play a crucial function.

Let’s examine engine valves to learn more about their construction, how they work, and the crucial role they play in our cars’ performance.

Valve Basics

Engine valves are metallic components that act as gates, controlling the intake of air and the expulsion of exhaust gases within the combustion chamber. Valves are typically made from durable alloys, such as stainless steel or heat-resistant alloys, to withstand high temperatures and repetitive motion.

Types of Engine Valves

Intake Valve

Positioned on the cylinder head, the intake valve allows the entry of air-fuel mixtures into the combustion chamber during the intake stroke.

Exhaust Valve

Located adjacent to the intake valve, the exhaust valve facilitates the exit of burned gases from the combustion chamber during the exhaust stroke.

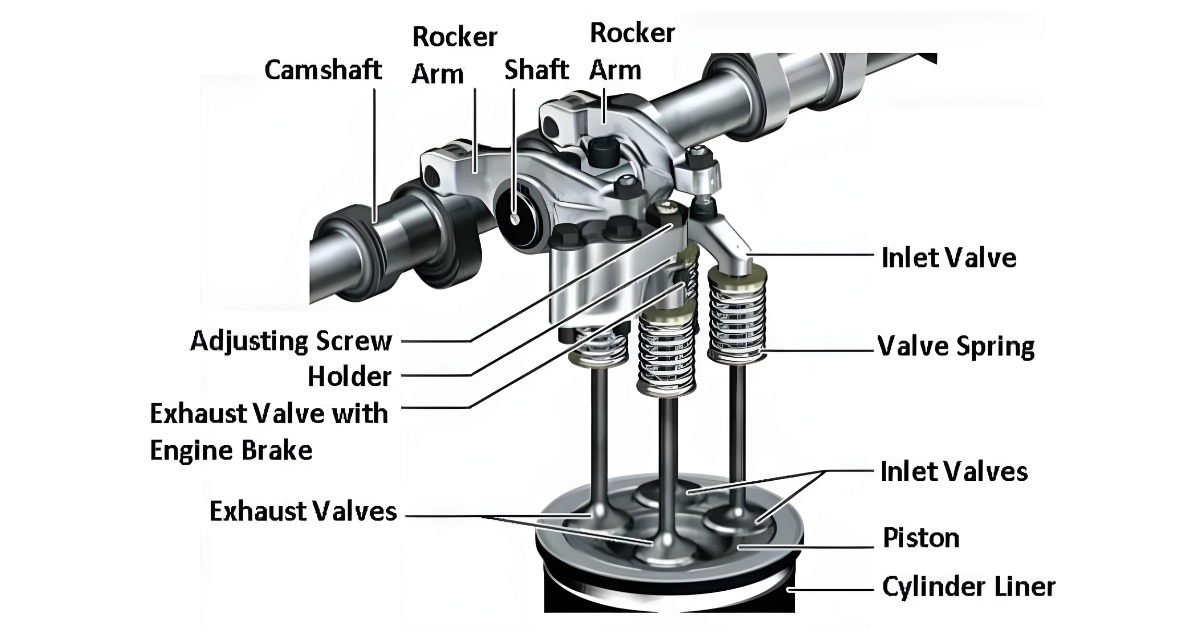

Valve Components

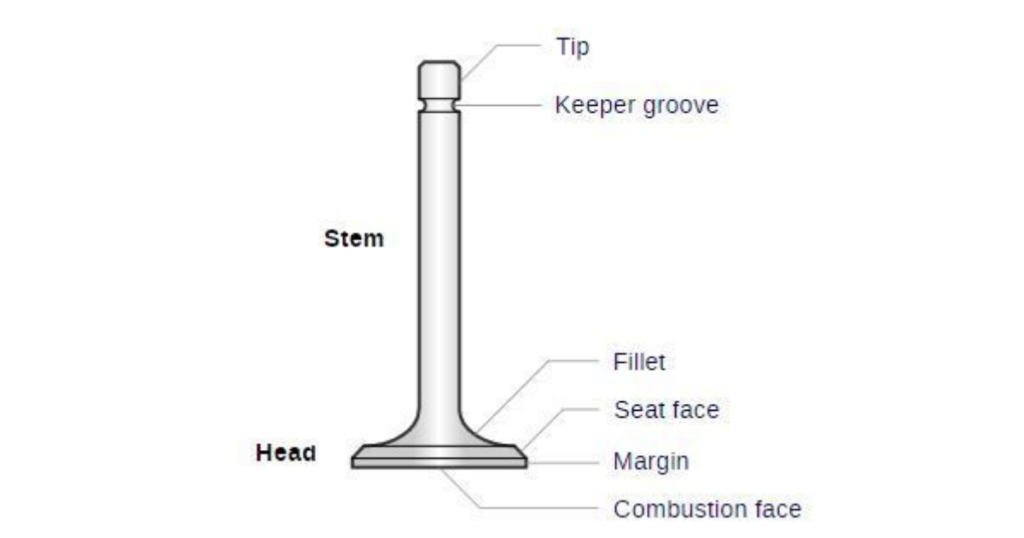

- Valve Head: The upper part of the valve that seals against the valve seat. It is shaped to optimize airflow and combustion efficiency.

- Valve Stem: The elongated, cylindrical portion of the valve that connects to the valve train and experiences reciprocating motion.

- Valve Face: The surface of the valve head that makes contact with the valve seat, forming a seal during combustion.

- Valve Seat: A machined surface in the cylinder head against which the valve face seals. The valve seat is crucial for maintaining compression and preventing gas leakage.

Valve Actuation

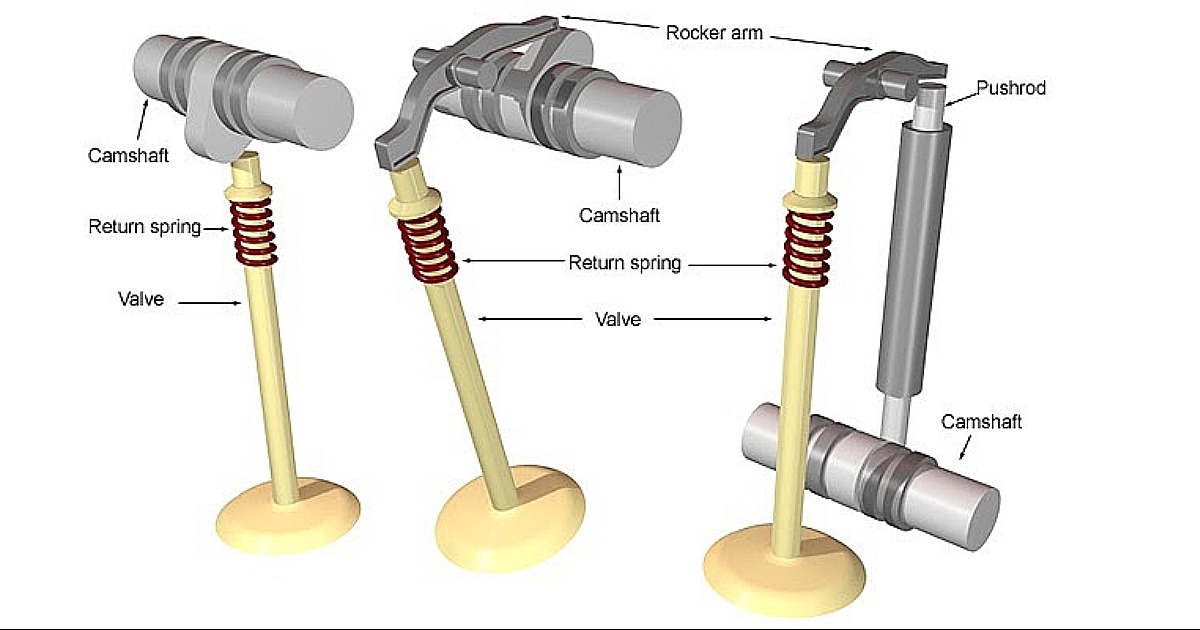

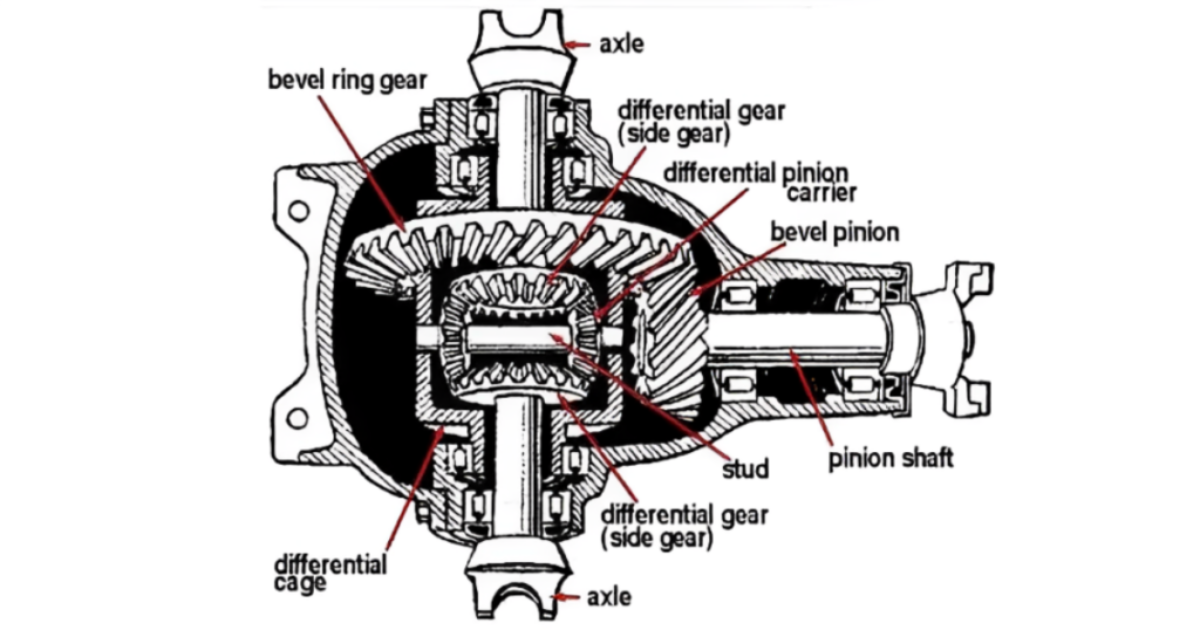

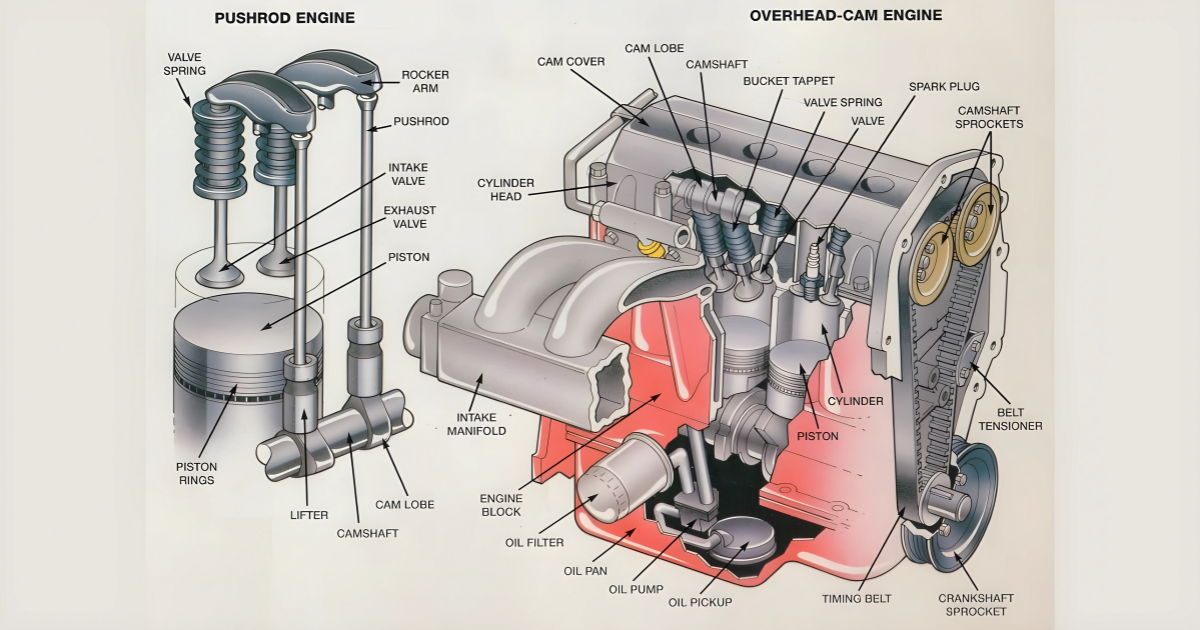

- Valve Train: The valve train consists of components like camshafts, lifters, pushrods, and rocker arms that work together to actuate the opening and closing of engine valves.

- Camshaft: The camshaft is a rotating shaft with eccentric lobes that control the lift and duration of the valve openings. It synchronizes with the engine’s rotation to precisely time valve events.

- Valve Lifters: Lifters are components that transfer the camshaft’s motion to the pushrods or directly to the valve stems, causing them to move up and down.

- Pushrods and Rocker Arms: In overhead valve (OHV) engines, pushrods transmit the motion from the lifters to rocker arms, which then actuate the valves. In overhead cam (OHC) engines, camshafts directly actuate the valves.

Functioning of Engine Valves

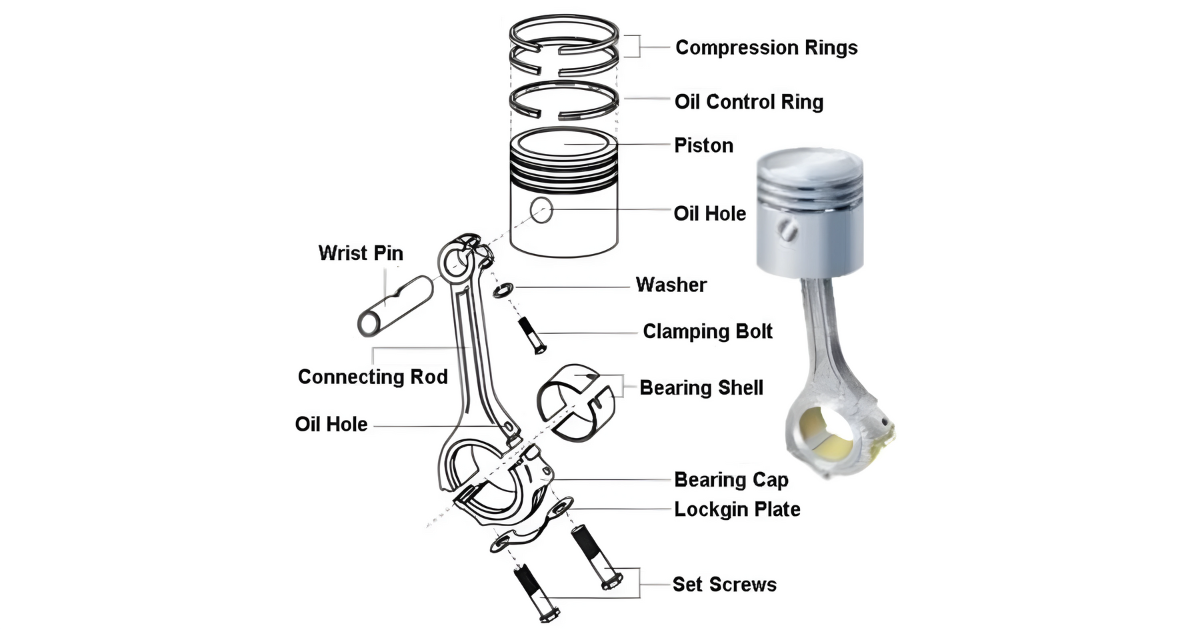

- Intake Stroke: During the intake stroke, the intake valve opens to allow the air-fuel mixture into the combustion chamber as the piston moves downward.

- Compression Stroke: Both valves close during the compression stroke, sealing the combustion chamber. The piston moves upward to compress the air-fuel mixture.

- Power Stroke: The spark plug ignites the compressed mixture, causing a rapid expansion of gases. The exhaust valve remains closed while the piston moves downward to generate power.

- Exhaust Stroke: As the piston ascends during the exhaust stroke, the exhaust valve opens, allowing the burned gases to exit the combustion chamber.

Challenges and Innovations

- Heat and Wear: Engine valves operate in extreme conditions, experiencing high temperatures and frequent motion. Innovations in materials and coatings, such as satellite or titanium, address issues of heat and wear, ensuring durability.

- Variable Valve Timing (VVT): VVT systems adjust the timing of valve opening and closing based on engine speed and load. This optimizes performance, fuel efficiency, and emission control.

- Multi-Valve Configurations: Many modern engines use multiple valves per cylinder, such as dual overhead cam (DOHC) setups, to enhance airflow and combustion efficiency.

Conclusion

Engine valves, which are often overlooked during the daily operation of our vehicles, play a crucial role in coordinating the intricate process of combustion. The design, materials, and actuation mechanisms play an important part in enhancing the efficiency and performance of internal combustion engines.

With the progress of automotive technology, valve technology is constantly evolving to improve efficiency, tackle challenges, and enable engines that are both sustainable and high-performing, driving us toward a future of exciting journeys.

For a comprehensive visual insight into engine valves, exploring their components and more, please take a look at the video below.