Under the chassis of every automobile, a crucial component silently facilitates smooth turns, seamless transitions, and the distribution of power between wheels—the conventional differential. As an integral part of the drivetrain, the differential plays a pivotal role in ensuring optimal vehicle performance.

In this exploration, we delve into the mechanics of the conventional differential, uncovering its functions, principles, and significance in the world of automotive engineering.

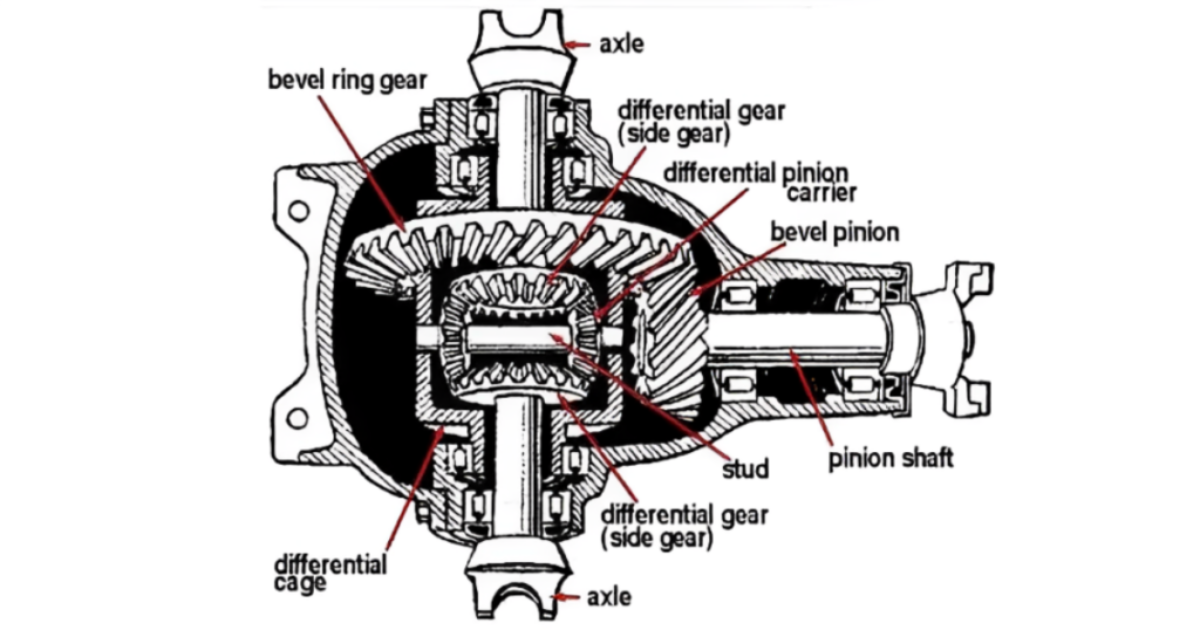

Conventional Differential Mechanism

The conventional differential, a mechanical component situated within the axle assembly, serves as a torque distributor between the drive wheels. Its purpose is to enable varying wheel speeds during turns by mediating between the engine and the wheels.

Typically positioned centrally or at the rear of the vehicle, the differential connects the two drive wheels, resolving the challenge of disparate wheel speeds and ensuring smooth operation during turns.

Basic Components and Design

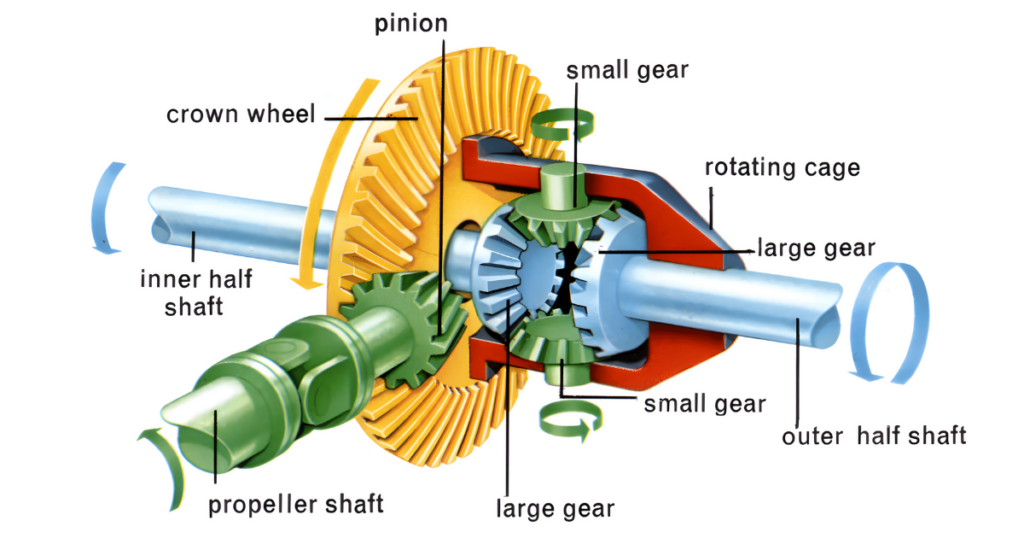

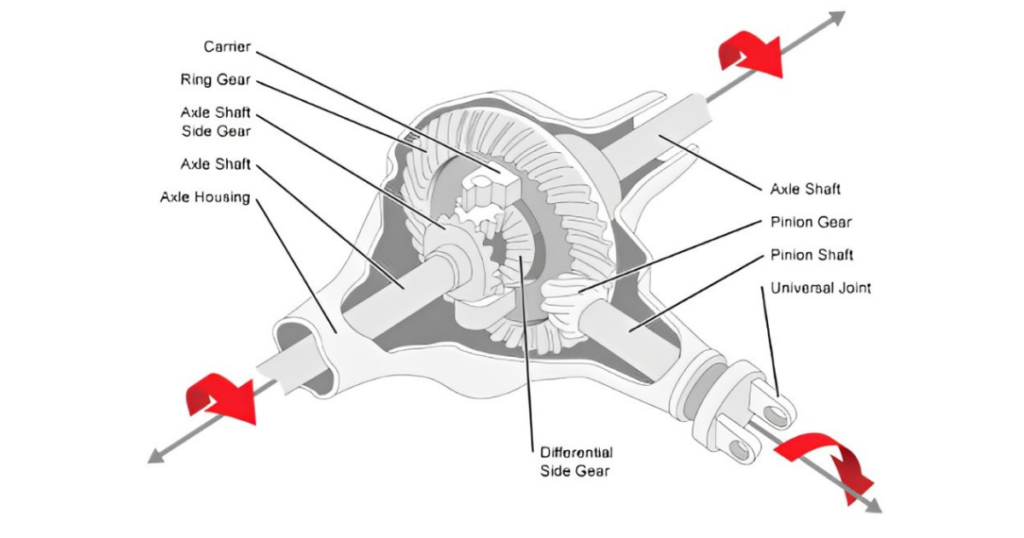

- Ring Gear and Pinion Gear: At the core of the conventional differential lie the ring gear and pinion gear. The ring gear encircles the differential case, while the pinion gear is connected to the driveshaft.

- Differential Case: The differential case houses the gears and serves as the central structure. It rotates with the pinion gear and distributes torque to the drive wheels.

- Spider Gears: Spider gears, also known as pinion gears, connect the differential case to the axles. They allow for differential wheel speeds during turns.

Functionality During Straight-line Driving

- Equal Torque Distribution: When a vehicle moves in a straight line, both drive wheels rotate at the same speed. The ring gear transfers torque from the pinion gear to the spider gears, which, in turn, transmit equal torque to both axles.

- Straightforward Operation: During straight-line driving, the differential operates seamlessly, ensuring both drive wheels receive an equal share of power from the engine.

Challenges During Turns

- Inner and Outer Wheel Speeds: During a turn, the inner wheel covers a shorter distance than the outer wheel, causing a speed difference between them. Without a differential, this variance would result in wheel slippage and potential damage to the drivetrain.

- Overcoming Wheel Binding: The differential allows the inner and outer wheels to rotate at different speeds, mitigating wheel binding and enabling smooth turns.

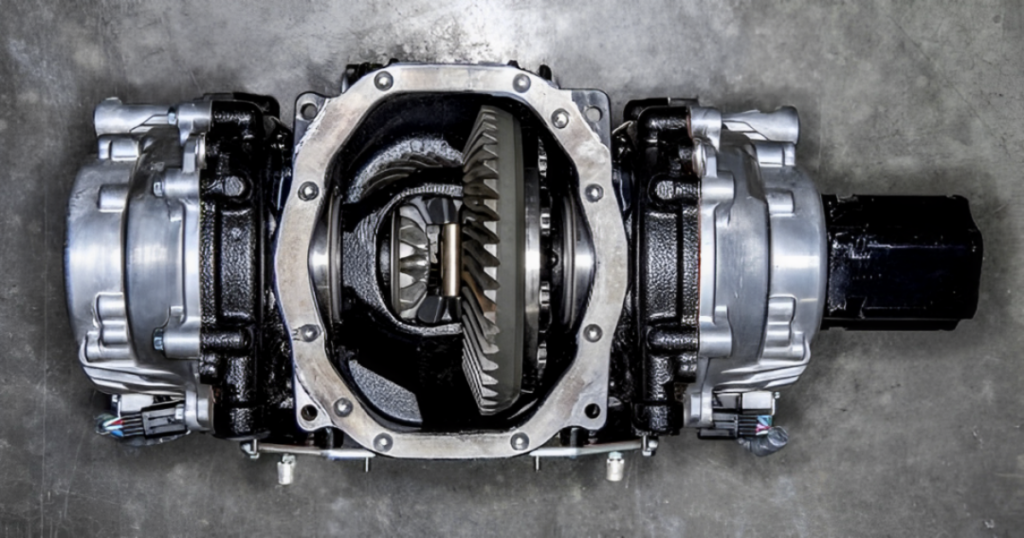

Limited-Slip Differential (LSD)

- Enhancing Traction: Some conventional differentials can be equipped with limited-slip functionality. LSDs distribute torque based on wheel slip, improving traction on uneven surfaces or during performance-oriented driving.

- Friction Plates: LSDs often incorporate friction plates or clutches that engage when wheel slip is detected. This provides additional torque to the wheel with better traction.

Maintenance and Lubrication

- Regular Inspections: To ensure proper functioning, it’s crucial to include the differential in routine vehicle inspections. Issues such as leaks, unusual noises, or excessive wear should be promptly addressed.

- Lubrication: The differential relies on lubricating oil to reduce friction and dissipate heat. Regularly changing the differential fluid is essential for maintaining optimal performance and longevity.

Off-Road and Performance Applications

- Enhanced Capability: Conventional differentials are widely used in off-road vehicles and trucks. Their simplicity and durability make them suitable for challenging terrains, although limited-slip or locking differentials may be preferred for extreme conditions.

- Performance Driving: While effective for daily driving, conventional differentials may exhibit limitations during high-performance driving. Enthusiasts may opt for advanced differential systems, such as electronic limited-slip differentials or torque vectoring differentials, to enhance handling and traction.

Conclusion

The conventional differential, often overlooked in its simplicity, plays a critical role in the overall dynamics of a vehicle. It embodies the elegance of engineering solutions, allowing wheels to rotate at different speeds during turns while maintaining stability and preventing wheel binding.

As automotive technology continues to evolve, differentials will likely see further enhancements, bringing new levels of precision and adaptability to the drivetrain. In the intricate dance between engine power and wheel rotation, the conventional differential remains a steadfast performer, ensuring that each turn is met with grace and efficiency on the open road.

For a visual insight into the workings of the Conventional Differential and the various types of Differentials, please watch the video below.