In the world of automotive engineering, the steering system plays a crucial role in effortlessly translating the driver’s commands into smooth changes in direction. Among the various steering systems, the hydraulic steering system stands out for its efficiency and widespread use in modern vehicles.

Let’s take a closer look at how hydraulic steering works and the different parts involved that contribute to a comfortable and responsive driving experience.

The Basics of Hydraulic Steering

Hydraulic steering is a power-assisted system designed to reduce the effort required for steering, particularly at low speeds and during parking maneuvers.

Process

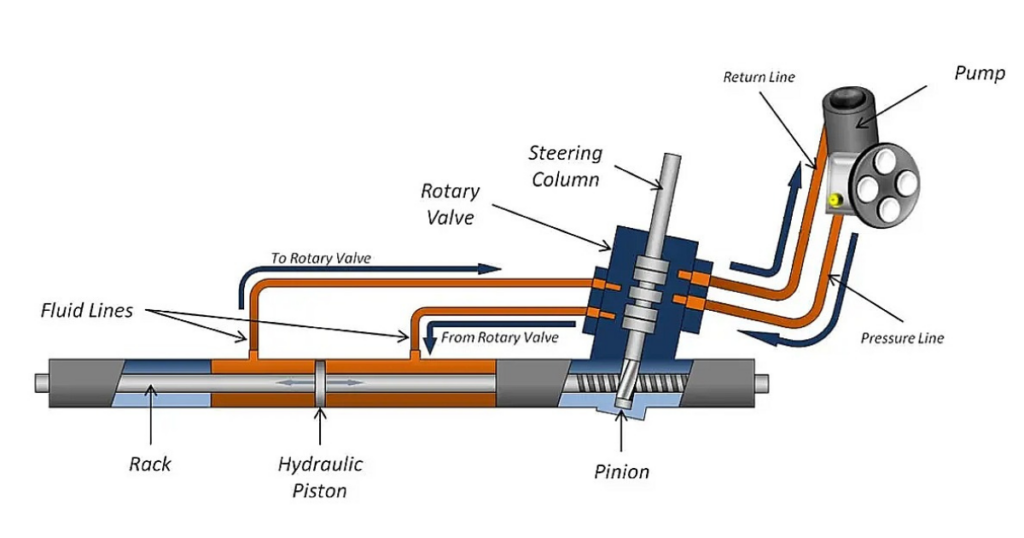

- Hydraulic Pump: Driven by the vehicle’s engine, the hydraulic pump is the heart of the system. It pressurizes hydraulic fluid (usually power steering fluid) to provide assistance to the driver.

- Hydraulic Fluid Reservoir: This reservoir stores the hydraulic fluid and ensures a constant supply to the system. It allows for the expansion and contraction of fluid due to temperature changes.

- Power Steering Lines: These lines transport pressurized hydraulic fluid from the pump to the steering gear and back to the reservoir, creating a closed-loop system.

- Steering Gear (Rack-and-Pinion or Recirculating Ball): The steering gear converts the rotational motion from the steering wheel into lateral motion at the vehicle’s wheels. Common types include rack-and-pinion and recirculating ball steering gears.

Rack-and-Pinion Steering System

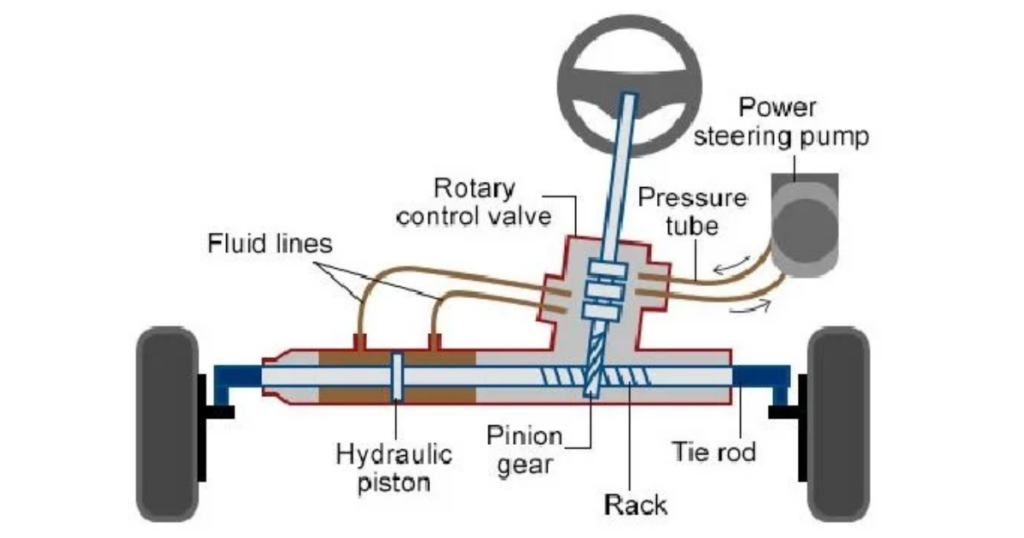

The rack-and-pinion steering system is prevalent in modern vehicles, providing a direct and responsive steering feel.

Process

- When the driver turns the steering wheel, the rotational motion is transferred to the pinion gear.

- The pinion gear engages with the rack, a linear gear, causing it to move laterally.

- This lateral movement is transmitted to the tie rods, which connect to the steering knuckles, ultimately turning the vehicle’s wheels.

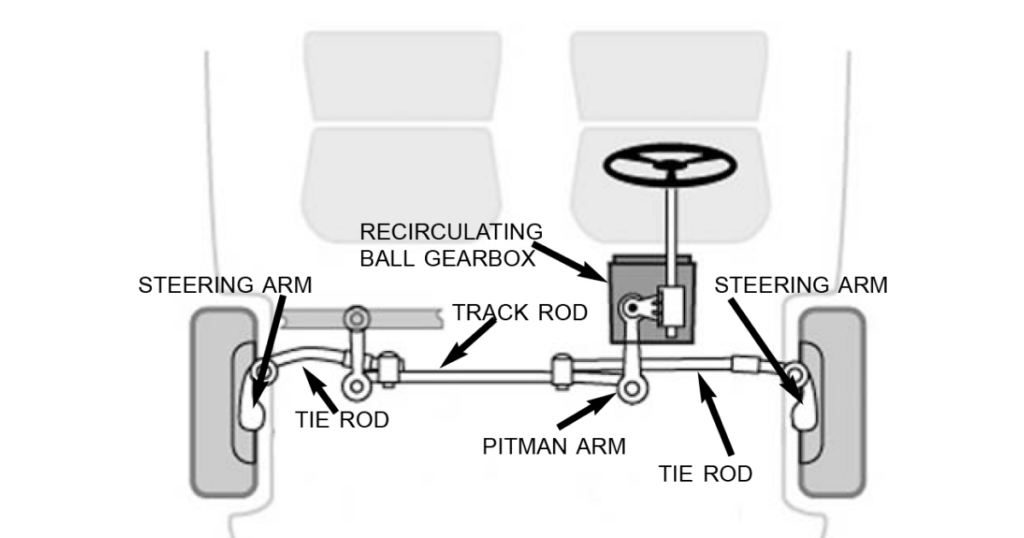

Recirculating Ball Steering System

While less common in modern vehicles, some trucks and larger vehicles still utilize recirculating ball steering systems.

Process

- Turning the steering wheel rotates a shaft that has a recirculating ball nut.

- The ball nut moves along a worm gear, causing the pitman arm to move.

- This motion is transferred to the steering linkage, resulting in the turning of the wheels.

Hydraulic Assist

Hydraulic steering provides power assistance to the driver, making it easier to turn the wheels, especially at low speeds or when stationary.

Process

- As the driver turns the steering wheel, a valve in the steering gear directs pressurized hydraulic fluid to one side of the piston.

- The pressure on the piston assists in moving the rack, providing a mechanical advantage to the driver.

- The hydraulic fluid then returns to the reservoir, ready for the next steering input.

Advantages of Hydraulic Steering

- Responsive and Direct: Hydraulic steering systems offer a responsive and direct connection between the driver’s input and the vehicle’s movement, providing a more engaging driving experience.

- Effort Reduction: The power assistance in hydraulic steering reduces the effort required by the driver, particularly in parking situations and at low speeds.

- Compact Design: Hydraulic steering systems, especially rack-and-pinion configurations, are known for their compact design, allowing for efficient use of space in the vehicle.

Maintenance and Common Issues

- Fluid Checks: Regular checks of the power steering fluid level and quality are essential for the system’s proper functioning.

- Leaks: Hydraulic steering systems can develop leaks in hoses or seals, leading to a decrease in power assistance and potential damage to the system.

- Pump Issues: The hydraulic pump may experience wear over time, affecting its efficiency and requiring replacement.

The Future of Steering Systems

Electric Power Steering (EPS). While hydraulic steering remains prevalent, Electric Power Steering (EPS) systems are gaining popularity. EPS uses an electric motor to provide assistance, offering efficiency benefits and adaptability for future autonomous driving technologies.

Conclusion

As we steer our vehicles through the twists and turns of daily life, the hydraulic steering system silently ensures a seamless and responsive driving experience. From the pump’s pressurized fluid to the intricate workings of the steering gear, each component plays a crucial role in translating the driver’s intentions into precise wheel movements.

While technology continues to advance, the hydraulic steering system remains a cornerstone of automotive engineering, embodying the delicate balance between driver control and power assistance. As we navigate the road ahead, the efficiency and reliability of hydraulic steering systems continue to be a testament to their enduring role in the evolution of vehicular dynamics.

For quick visual insight and a deeper understanding of hydraulic steering systems, watch the video below covering hydraulic assist power steering.