Discover the key steps to take after replacing your car’s crankshaft sensor, ensuring optimal performance and reliability. Dive into our guide for a smooth, hassle-free experience that keeps your engine running like a dream.

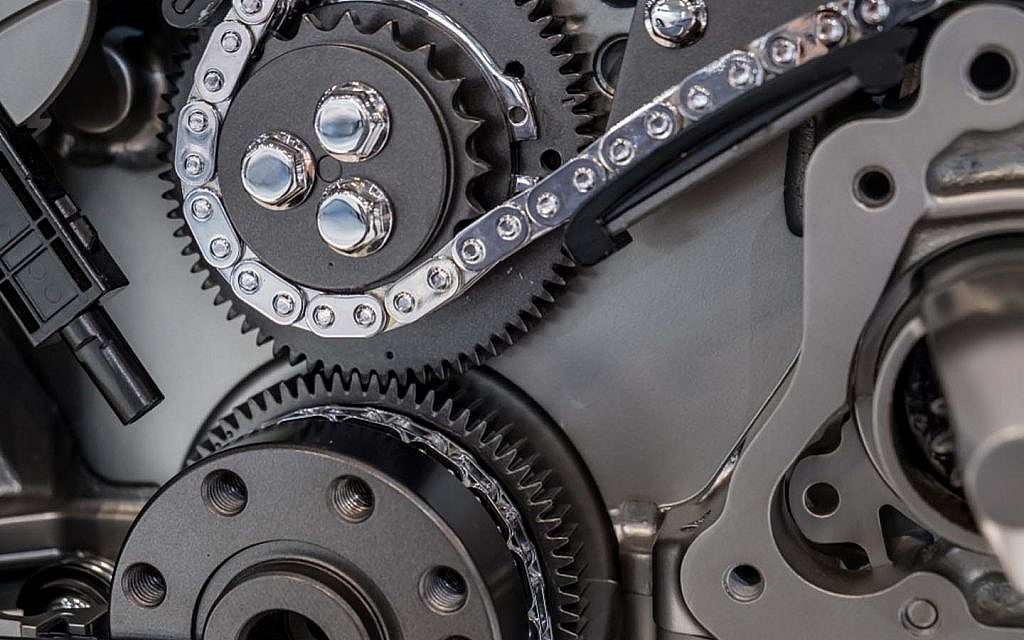

Crankshaft Sensor (Defined)

Crankshaft position is measured by an electronic device in internal combustion engines that run on diesel or petrol. After taking readings, it will transmit signals to the car’s computer that will be interpreted as data on where in the cylinder the piston is.

Crankshaft rotational velocity is also shown, along with its geographical position. Structures in the engine control module use these numbers to adjust the timing of the ignition machines, the amount of gasoline injected, and other engine parameters.

What to Do After Crankshaft Sensor Replacement

Remove the error code and double-check the crankshaft sensor installation after completing this procedure. Here is a detailed guide to what you should do after the replacement.

1. Check the Installation

Check to see that the installation is completed correctly. Extreme caution must be exercised during the installation process. You absolutely do not want to replace the position of A with B.

If you make a mistake, your car might not start or, at the very least, the “check engine” light might come on.

Knowing the proper method for installing a crankshaft sensor is the only way to tell if one has been put in. Knowing this will allow you to compare the variables and identify any gaps.

Here is a basic checklist to follow to assist you in evaluating what you currently have.

- It’s important to confirm if the camshaft is broken before paying for a replacement; in many cases, the crankshaft sensor is OK. Keep your cool and operate the vehicle with a code scanner. If you get a P0335 code, you know the crankshaft sensor needs to be changed.

- Find the position of the crankshaft position sensor by consulting the user handbook. If you’re still having trouble, the crankshaft sensor is housed in the crankcase above the crankshaft’s toothed wheel.

Now that you’ve found it, we may continue with changing your crankshaft sensor.

- Turn off the motor vehicle.

- When you park your automobile for the night, give it time to cool down. Remove the negative battery cable when the car has cooled down to a manageable temperature.

- The crankshaft sensor is held together by a bolt, which should be loosened. This can be done quickly and easily with your fingertips, or you can use a tool if you prefer.

- Take the worn-out sensor off of the motor. Make that the electrical connection to the crankshaft is severed.

- The crankshaft sensor and the O-ring should each receive a light coating of oil.

- To keep the new sensor in place, simply reverse the previous steps after replacing the old one.

If, after inspecting the processes, you find that the installation went off without a hitch, then you’re good to go. The cables can also be inspected.

Corroded wires are another common cause of a nonstarting vehicle. The following step is to reset the crankshaft sensor’s position once you’re finished.

2. Reset the Crankshaft Sensor.

After ensuring the crankshaft sensor is installed properly, you should reset it so the engine warning light doesn’t stay on. You can use a scanner to reset your crankshaft sensor or do it manually.

Crankshaft Sensor Re-learning Using a Scanner

- The first step is to link the code scanner to the vehicle. There, you will get a signal that says DTC P1336 CKP variation not learned.

- Now that you’ve put the car in park, you can turn the key and go.

- Please pause the engine for a second.

- To initiate the sensor’s learning process, set your scanner to CASE Learn.

- Press the brake and keep it pressed down firmly before starting the engine again.

- By reading it, determine whether or not the engine DTC is a CASE learned to code.

- The reset is finished if it is learned. If it isn’t, then you need to get a second opinion.

- Get rid of the error message and try again.

How to Reset the Crankshaft Position Sensor Manually

It’s totally fine if you don’t have access to a scanner. You can quickly reset your camshaft sensor by speeding up and slowing down your vehicle in accordance with the guidelines provided.

1. Acceleration-Deceleration Cycles

One way to reset the crankshaft position sensor without a scanner is to accelerate and decelerate the vehicle at specific rates repeatedly. Here is a simplified rundown of the procedure:

- Turn off the car’s stereo and any other unnecessary gadgets.

- The coolant and air temperature sensors should remain within a narrow range of one another.

- Idling the engine in Park or Neutral is required for at least two minutes.

- Go up to around 55 miles per hour, but don’t floor it.

- Maintain this rate for a minimum of a few minutes to get the engine up to temperature.

- For the next minute, please slow down to 45 miles per hour.

- Apply no brakes for 25 seconds while repeating the same deceleration cycle.

- Between deceleration cycles, speed up to 45 mph for 15 seconds.

- Repeat the previous step and maintain 55 mph for the remaining driving time.

- Turn off your car’s engine and let it sit for a while.

If you follow these instructions correctly, the crankshaft position sensor can be reset without a scanner. If this approach is too much work, there is another option.

2. Disconnecting the Battery

The crankshaft sensor may also be reset by removing the battery, which is something many people wonder about. You can deplete the power from your vehicle’s electrical components by disconnecting the negative terminal of the battery and letting the car sit for at least an hour before reconnecting it.

Likewise, the ECU will have no more working memory. When the electronic control unit’s memory is cleared, it will re-learn the crankshaft sensor’s location the next time the engine is started. The only drawback of this simple procedure is the length of time it may take for all electrical components to lose power.

If the check engine light was on after rebuilding the crankshaft, resetting the sensor should turn it off. If the problem is with the crankshaft position sensor, the car wouldn’t start or will stall.

When Should A Crankshaft Position Sensor Be Replaced?

Crankshaft position sensors need to be changed when;

1. The Warning Light Has Come On

The check engine light is the primary indicator that a camshaft sensor needs replacement. But you must ensure the issue is indeed caused by the camshaft sensor. This can be a quick way to determine if your camshaft sensor is malfunctioning, but you should also look for other signs.

2. Extreme Vibration from the Engine

An abnormal vibration is one of the telltale signs of a defective camshaft position sensor. A rough ride is a surefire way to notice this.

A subpar driving experience might be expected if the camshaft sensor fails to do its job. If you’re experiencing exceptionally rough riding or a great deal of engine vibration, you should check your camshaft sensor.

3. Reduced Engine Efficiency

When the acceleration and deceleration aren’t what they should be, you can see right away that the engine isn’t performing at peak efficiency.

4. Poor Gas Mileage

A malfunctioning camshaft sensor will not only lead to a decrease in speed but also in fuel economy.

5. Trouble Jumpstarting Your Vehicle

A faulty camshaft sensor might also make starting or maintaining engine operation impossible. This is unlikely to occur unless you have neglected the issue for an extended period.

FAQs

How to fix a bad crankshaft sensor?

A faulty crankshaft sensor is not repairable and must be replaced. Crankshaft sensors can be easily replaced by the car owner for a cost of $66 and $341.

Why won’t my car start after replacing the crankshaft sensor?

A new crankshaft sensor should not have stopped the car from starting. The car won’t start because of a problem with the fuel or ignition or because of something that happened when the crank sensor was changed.

Does a new crankshaft sensor have to be programmed?

No, most crank position sensors are hall-effect sensors, which are flaky and fragile.

What is the most common problem with crankshaft sensors?

Difficulty starting the car is the most prevalent sign of a faulty crankshaft position sensor. The crankshaft position sensor is responsible for tracking crucial engine-starting characteristics like crankshaft position and speed.

How long does a crankshaft sensor last?

Crankshaft position sensors often last the lifespan of the vehicle and do not need to be replaced at regular intervals. Nonetheless, failure is not unheard of, and the odds of it happening increase beyond 100,000 miles.

Final Words

It is possible that you will run into a few issues after you have replaced your crankshaft sensor; nevertheless, you should not panic. After making any repair, you need to double-check that the installation procedure was carried out correctly by ensuring there is no short to ground and the battery terminals are not wobbly.

If your vehicle is still not starting, the short circuit likely occurred somewhere in the engine wiring harness. Also, reset the crankshaft position sensor to avoid further frustrating results.