When it comes to keeping everyone safe on the road, the braking system of a vehicle is of utmost importance. Whether you’re driving through busy urban areas or on long stretches of open road, having a good grasp of how a braking system functions is crucial for feeling secure behind the wheel and ensuring safety on the road.

Let’s “brake” it down and have a closer look at how a vehicle is able to come to a stop, examining the different parts, their roles, and the science behind slowing down.

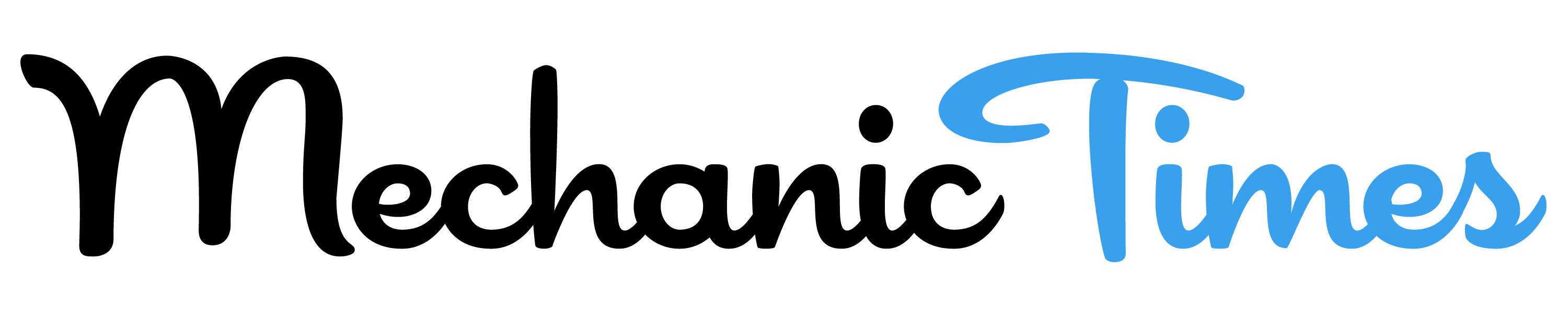

Components of a Braking System

- Brake Pedal: The journey begins with the driver’s foot on the brake pedal. The brake pedal serves as the interface between the driver and the braking system, initiating the deceleration process.

- Master Cylinder: Connected to the brake pedal, the master cylinder is a hydraulic device that converts the mechanical force applied by the driver into hydraulic pressure.

- Brake Lines: Hydraulic pressure generated by the master cylinder travels through brake lines, delivering the force to the braking components at each wheel.

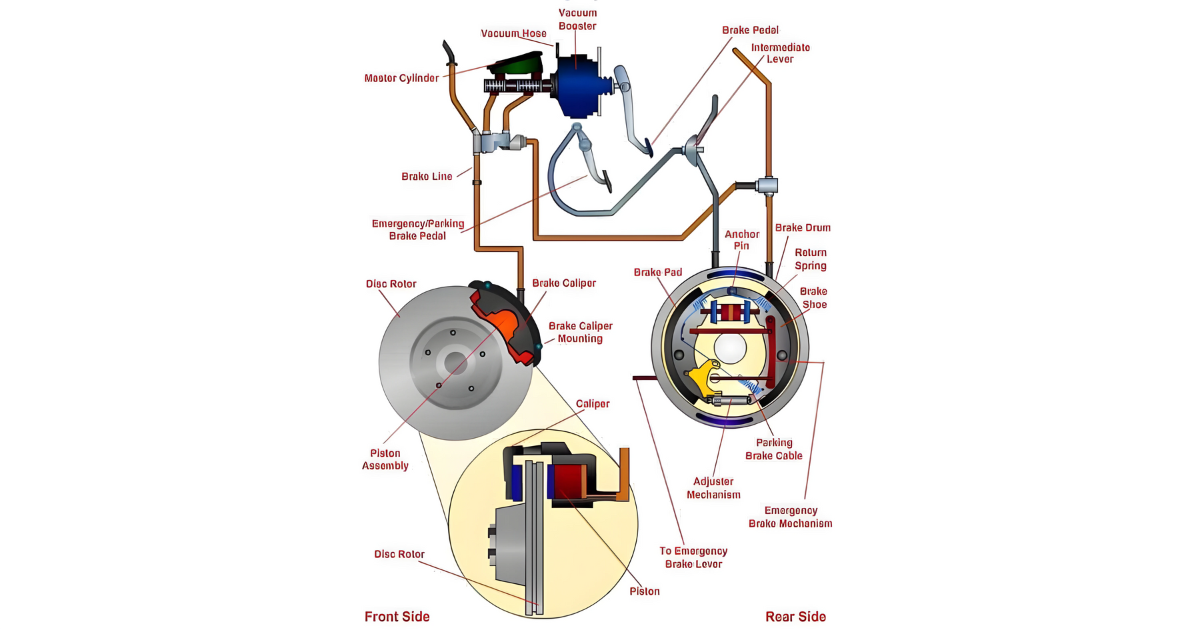

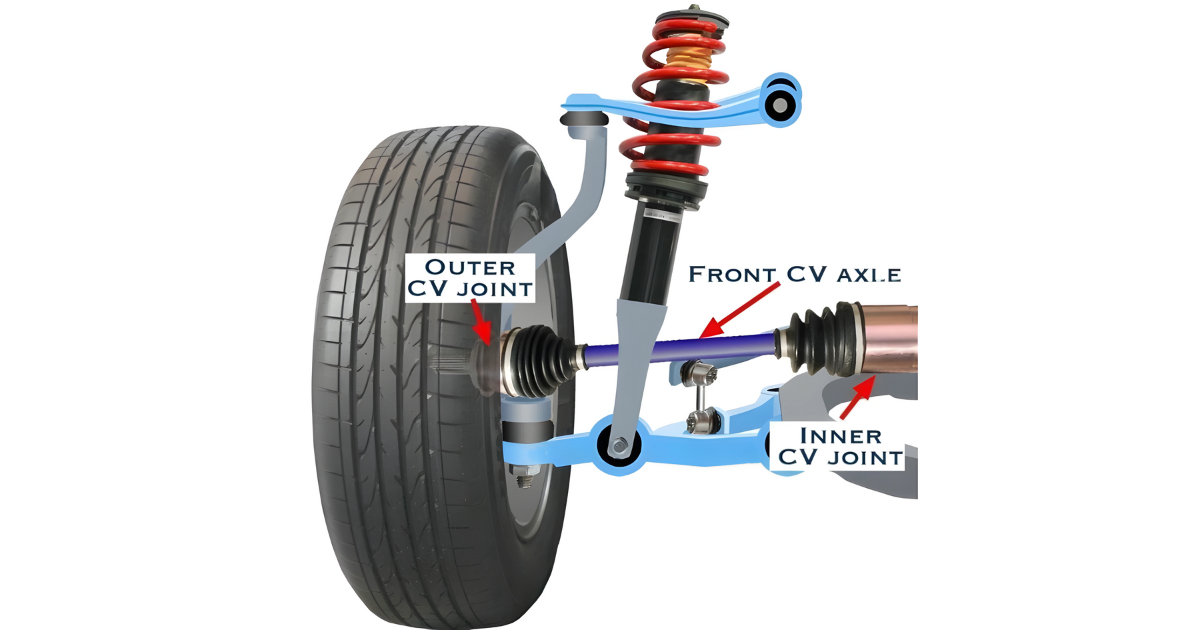

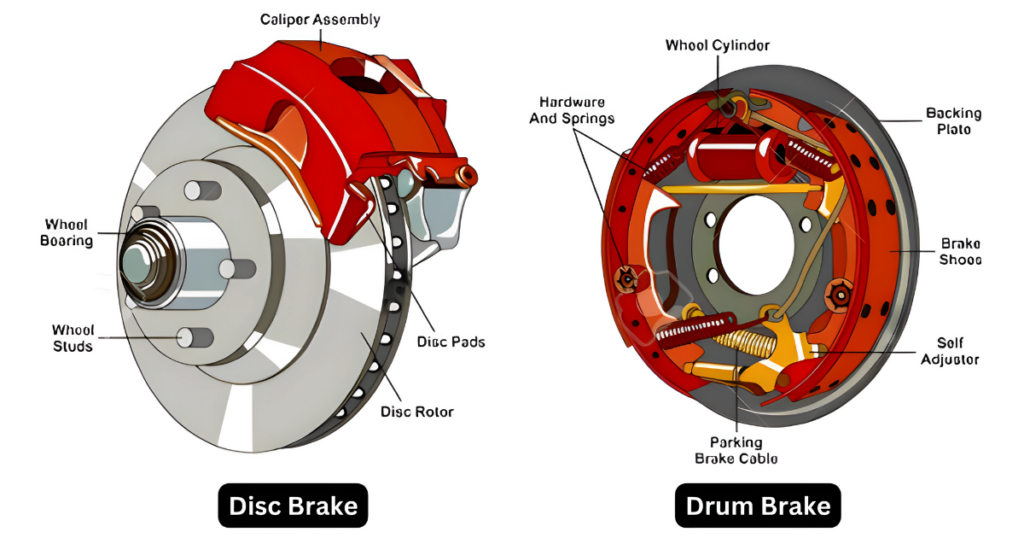

- Brake Calipers (Disc Brakes) or Wheel Cylinders (Drum Brakes): These components convert hydraulic pressure into mechanical force, squeezing brake pads against a disc or brake shoes against a drum, initiating the friction necessary for deceleration.

- Brake Pads (Disc Brakes) or Brake Shoes (Drum Brakes): These friction materials make direct contact with the rotating components (disc or drum) to generate the necessary resistance for slowing down the vehicle.

- Rotors (Disc Brakes) or Drums (Drum Brakes): The rotating components against which the brake pads or shoes apply pressure. In disc brakes, rotors are flat, while drums in drum brakes have a cylindrical shape.

Hydraulic Pressure and Mechanical Force

- Brake Fluid: The master cylinder is filled with brake fluid, a hydraulic medium that transmits pressure effectively. Brake fluid is chosen for its ability to withstand high temperatures and maintain consistency.

- Hydraulic Multiplication: When the driver applies force to the brake pedal, the master cylinder multiplies this force hydraulically. This multiplication is crucial for generating sufficient pressure to engage the braking components effectively.

Drum Brake vs Disc Brake

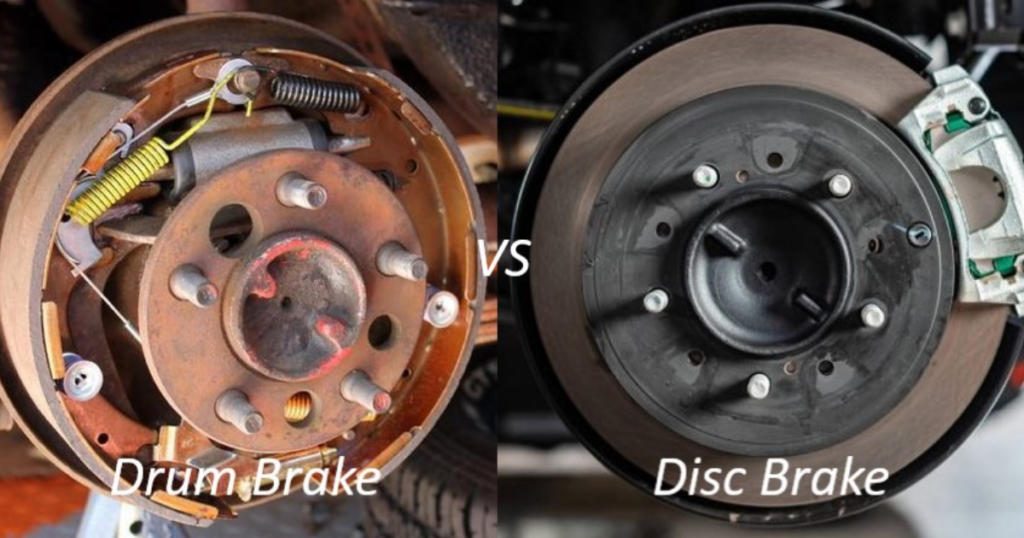

- Disc Brakes: In disc brake systems, calipers squeeze brake pads against flat rotors attached to the wheel. Disc brakes are known for their efficient heat dissipation, making them suitable for high-performance and heavy-duty applications.

- Drum Brakes: Drum brake systems use wheel cylinders to push brake shoes against the interior surface of a drum. While common in rear-wheel configurations, drum brakes are generally less effective in heat dissipation but are cost-effective and durable.

Friction, Heat, and Kinetic Energy

- Friction Generation: When brake pads or shoes make contact with the rotating disc or drum, friction is generated. This friction converts the kinetic energy of the moving vehicle into heat.

- Deceleration Process: As kinetic energy is converted into heat, the vehicle slows down. The higher the friction generated, the quicker the deceleration.

Anti-lock Braking System (ABS)

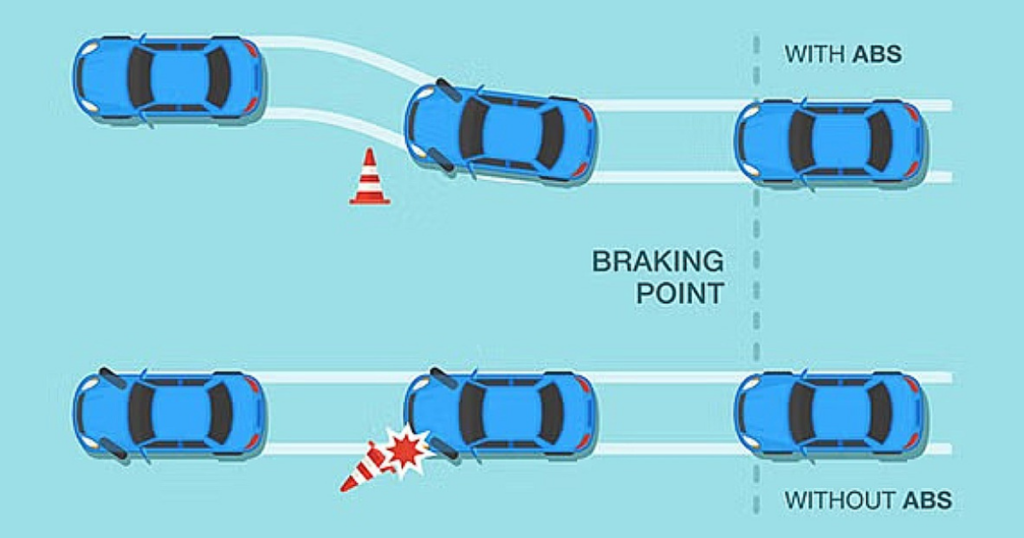

- Preventing Wheel Lockup: ABS is a safety feature designed to prevent wheel lockup during heavy braking. It modulates brake pressure, allowing the wheels to maintain traction with the road and reducing the risk of skidding.

- Electronic Sensors: ABS utilizes electronic sensors to monitor wheel speed. If a wheel is about to lock up, the system momentarily reduces brake pressure on that wheel, preventing a skid.

Electronic Brake-force Distribution (EBD)

EBD is a system that optimizes the distribution of braking force to each wheel based on the load it carries. This enhances stability and reduces the risk of wheel lockup.

Regenerative Braking (in Electric Vehicles)

In electric vehicles, regenerative braking captures kinetic energy during deceleration and converts it into electrical energy. This energy is then fed back into the vehicle’s battery for later use, improving overall efficiency.

Regular Maintenance and Inspection

- Brake Pad/Shoe Wear: Regular checks on brake pads or shoes are essential to ensure they have sufficient thickness. Worn-out pads or shoes can compromise braking performance.

- Brake Fluid Levels: Maintaining the proper level of brake fluid is crucial for the hydraulic system’s effectiveness. Low brake fluid levels can result in a soft brake pedal and reduced braking performance.

- Rotor/Drum Inspection: Rotors and drums should be inspected for signs of wear, scoring, or warping. Damaged rotors or drums can lead to uneven braking and vibration.

Conclusion

Understanding the mechanics of a braking system is like figuring out the code of vehicle safety. From the brake pedal to the detailed connection of different elements, each part has an important role in enabling a vehicle to safely come to a stop. With the progress of automotive technology, new features such as ABS, EBD, and regenerative braking are making braking systems safer and more efficient.

With this knowledge, drivers can appreciate the engineering prowess behind the seemingly simple act of bringing a vehicle to a halt and make informed decisions to ensure their safety on the road.

For an intriguing visual exploration of how the braking system works, check out the video below.