Turbochargers are very modest devices that have greatly improved the efficiency and power of engines in automobiles. These small parts are vital for improving the airflow to an engine, which in turn increases its production.

We will explain the science behind turbochargers and how they work by looking at each of their parts and explaining how they get their power boost.

The Basics of Turbocharging

Turbocharging is a forced induction system designed to maximize an engine’s power output by increasing the density of the air entering the combustion chamber. Unlike naturally aspirated engines that rely solely on atmospheric pressure to fill the cylinders with air, turbocharged engines use a turbocharger to compress the air, allowing more oxygen to be introduced during combustion.

Turbocharger Components Breakdown

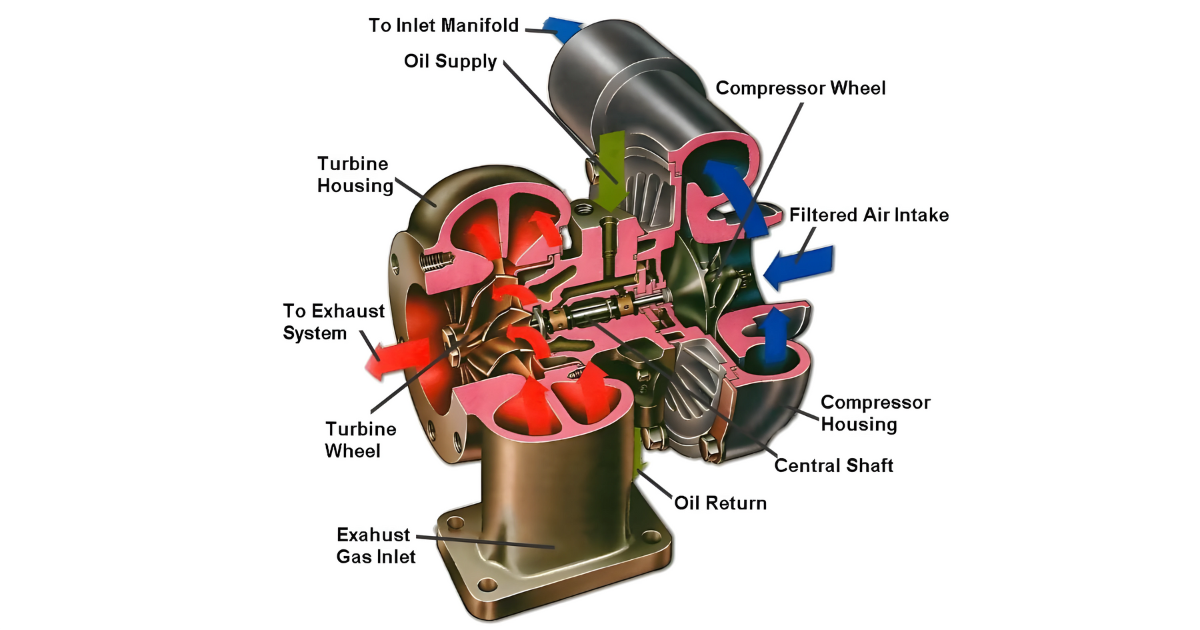

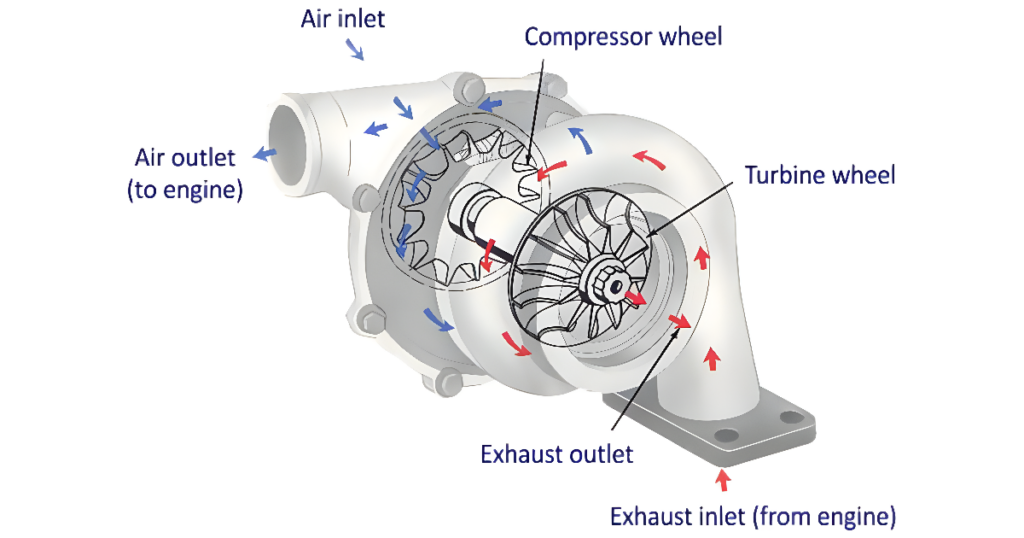

- Turbine Housing: At the heart of a turbocharger is the turbine housing. This component houses the turbine wheel, which is connected to the exhaust manifold. As exhaust gases exit the engine, they flow through the turbine housing, causing the turbine wheel to spin.

- Compressor Housing: Connected to the turbine housing is the compressor housing. Within this housing resides the compressor wheel. As the turbine wheel spins, it, in turn, drives the compressor wheel. The compressor wheel draws in and compresses ambient air before directing it into the engine’s intake manifold.

- Center Housing and Bearings: The center housing encases the shaft connecting the turbine and compressor wheels. The shaft rotates on bearings, ensuring smooth and efficient operation. Modern turbochargers often utilize ball bearings for reduced friction, enhancing responsiveness and durability.

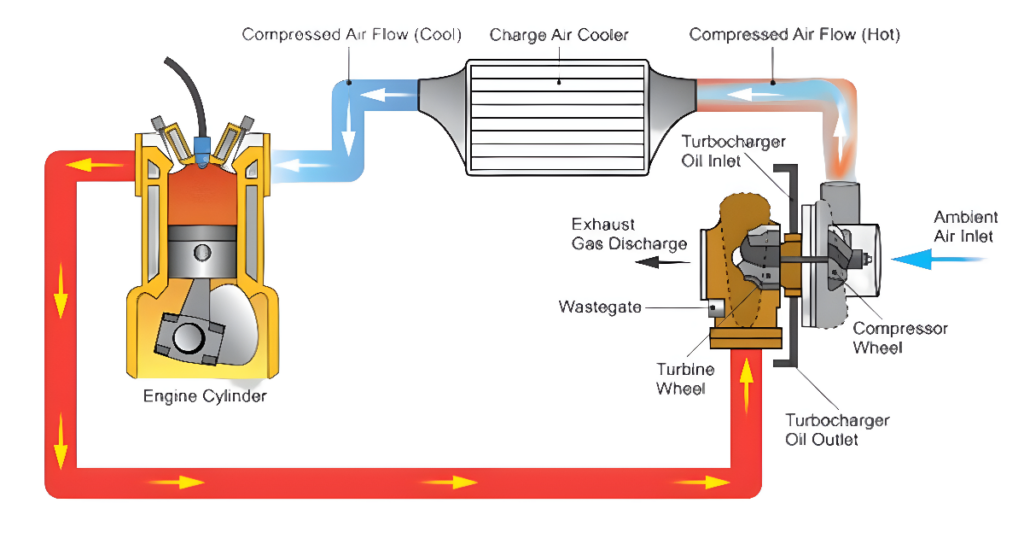

- Wastegate: To prevent excessive boost pressure, a wastegate is incorporated into the turbocharger system. The wastegate acts as a pressure-relief valve, allowing some exhaust gases to bypass the turbine wheel. This controls the speed of the turbine and regulates boost pressure to prevent over-boost, optimizing engine performance.

- Intercooler: While not directly within the turbocharger, the intercooler is an integral component of the forced induction system. Placed between the turbocharger and the engine’s intake manifold, the intercooler cools the compressed air before it enters the engine. Cooler air is denser, providing a more oxygen-rich mixture for combustion and further enhancing performance.

The Turbocharging Process

- Exhaust Gas Drives the Turbine: The process begins with the engine’s exhaust gases flowing into the turbine housing. These high-velocity gases cause the turbine wheel to spin, harnessing the energy from the exhaust.

- Compressor Wheel Compresses Air: As the turbine wheel turns, it’s connected to the compressor wheel via the shaft. The spinning motion of the turbine wheel drives the compressor wheel, which draws in and compresses ambient air, creating a pressurized air stream.

- Boosted Air Enters the Engine: The compressed air is then directed into the engine’s intake manifold, where it mixes with fuel for combustion. The increased air density allows for more fuel to be burned, resulting in a more powerful explosion within the cylinders.

- Enhanced Combustion and Power Output: The enriched air-fuel mixture leads to more forceful combustion, generating increased power and torque. This process is commonly referred to as forced induction, as the turbocharger forces more air into the engine than it would naturally draw.

Benefits of Turbocharging

- Increased Power and Torque: The primary benefit of turbocharging is the substantial increase in power and torque, providing enhanced acceleration and overall performance.

- Improved Fuel Efficiency: Turbochargers allow smaller, more fuel-efficient engines to deliver the power of larger ones. This downsizing, known as engine downsizing, can result in improved fuel efficiency without compromising performance.

- Reduced Emissions: The efficiency gains from turbocharging often translate into reduced emissions. Smaller, turbocharged engines can maintain performance while meeting stringent emission standards.

- Adaptability Across Engine Types: Turbocharging is versatile and can be applied to various engine types, including gasoline, diesel, and hybrid powertrains, showcasing its adaptability across the automotive landscape.

Conclusion

The turbocharger is a wonder of efficiency and power development in the field of automotive engineering. Its intricate components combine to compress air, capture exhaust energy, and provide a performance boost that has come to be associated with contemporary high-performance engines.

Comprehending the inner workings of a turbocharger not only helps enthusiasts appreciate the power, efficiency, and innovation that turbocharging brings to the road, but it also simplifies this engineering wonder.

For a visual insight into the functioning of a turbocharger, check out the animated video below.