Dive into the mechanical heart of your vehicle and explore the pivotal role of rod bearings in your engine’s symphony. Unravel the mystery behind their wear and tear, and embark on a journey to master their replacement. This guide is your roadmap to restoring harmony under the hood, ensuring your car runs smoother and quieter.

In an automobile engine, the rod bearing supports the rotating shaft. Even though it’s a plain bearing, it’s not the same as a ball bearing with tiny balls. By supporting the rotating shaft, this bearing enables the rod to remain straight during the combustion cycle. A rod bearing may also be called a “connecting rod bearing.”

The rod bearings in the car can cause issues with the engine, such as knocking, power issues, or even the car’s incapacity to drive. Moving forward, we will discuss the costs, procedures, and other factors in replacing a damaged rod bearing.

The average cost of replacing a rod bearing can range from $10 to $5,000. Such a broad range is due to multiple variables influencing the final price, such as whether you want to hire a professional mechanic or do it yourself.

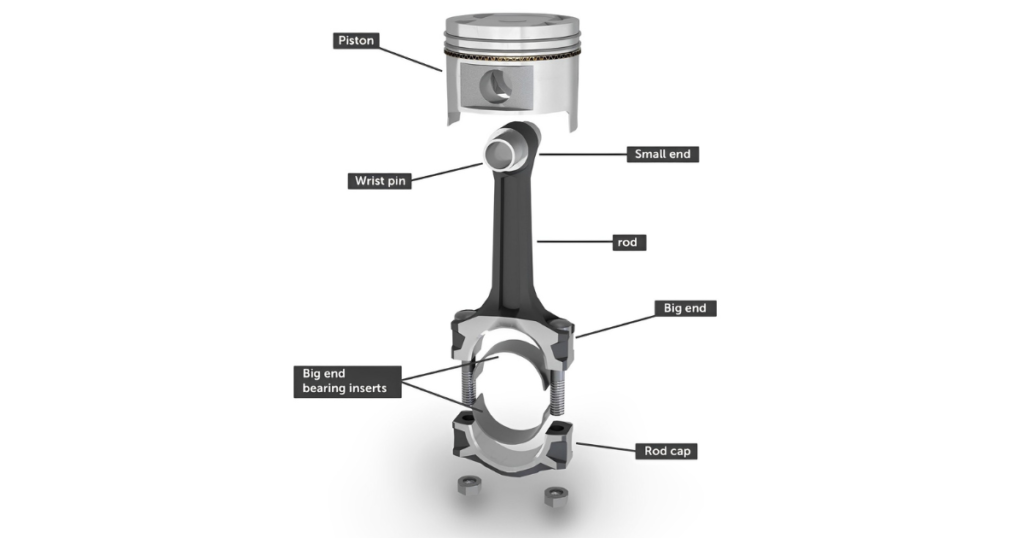

What Is Rod Bearing?

Rod bearings, unlike ball bearings, are plain bearings that rely on friction and oil supply for smooth rotation. They facilitate the movement of the connecting rod as the crankshaft rotates. These bearings have a pinhole near the top, which allows lubricant to reach the interior, ensuring proper lubrication and reduced friction within the bearing.

This design enables free rotation of the crankshaft while maintaining optimal performance and minimizing wear and tear on the engine components. The combination of friction reduction and efficient oil supply is crucial for the longevity and smooth operation of the engine.

What Is Included In Rod Bearing Replacement?

Replacing rod bearings is a critical task that requires careful consideration. While it is recommended to entrust this job to a professional, if you choose to do it yourself, precautions must be taken to avoid damaging engine components.

The process involves disassembling the engine to separate the connecting rods from the crankshaft. Keeping the bearing end caps and connecting rods matched correctly is crucial. One should clean the bearing surfaces thoroughly to prevent dirt and debris from causing bearing failure.

Moreover, it includes the installation of new bearings to ensure proper alignment and a snug fit. Precision and attention to detail are key when replacing rod bearings, whether you opt for professional assistance or undertake the task yourself.

What Will Happen If Rod Bearing Is Not Replaced?

Neglecting to replace worn or faulty rod bearings can lead to severe engine damage. Without proper friction, the connecting rods can separate from the crankshaft, causing harm to the cylinder bore and engine block. It is crucial to promptly address rod-bearing issues to prevent further complications or engine failure.

Cease driving the vehicle and seek professional assistance to rebuild or repair the engine. Proactive maintenance and timely repairs are essential for preserving engine health and performance.

Common Symptoms Indicating The Need To Replace Rod Bearings

Rod bearings play a crucial role in the smooth operation of your engine. When these bearings wear out or become faulty, certain symptoms may arise, indicating the need for replacement. Below are some common signs to watch out for:

Knocking or Rattling Noises:

One of the most noticeable symptoms is a knocking coming from the engine. This noise may be more pronounced during acceleration or at higher RPMs. It can indicate excessive wear on the rod bearings, resulting in a loose connection between the connecting rods and the crankshaft.

Low Oil Pressure:

Damaged rod bearings can lead to decreased oil pressure in the engine. A warning light on the dashboard or a low oil pressure reading on the gauge may indicate a problem with the bearings. Insufficient lubrication can accelerate wear and increase the risk of engine damage.

Engine Misfiring or Loss of Power:

Worn rod bearings can cause irregular engine firing or misfires, leading to a noticeable loss of power and performance. This can result in reduced acceleration, sluggishness, or an overall decrease in engine responsiveness.

Vibrations or Rough Running:

Faulty rod bearings can create vibrations or a rough running sensation in the engine. These vibrations can be felt throughout the vehicle, especially when idling or operating at low speeds. The uneven rotation caused by worn bearings disrupts the engine’s smooth operation.

Increased Oil Consumption:

Excessive oil consumption can be a sign of rod-bearing issues. Damaged bearings can lead to oil leaks or increased oil consumption as oil escapes through the worn gaps. If you find yourself frequently adding oil or notice oil stains under the vehicle, it may indicate a problem with the rod bearings.

Cost Of Replacing Rod Bearings

Rod bearings play a vital role in the smooth operation of an engine by reducing friction between the connecting rod and the crankshaft. Over time, these bearings can wear out and require replacement. However, the cost of this repair can vary significantly depending on several factors.

We will explore the average cost to replace rod bearings, considering whether the job is performed by a mechanic or as a DIY project. Please note that the figures provided are based on the national average and may not include additional fees, taxes, or expenses for your vehicle’s make and model.

Let’s delve further into different factors involved in the total cost and better understand it.

Labor Costs

Labor costs play a significant role in determining the overall expense of rod-bearing replacement. The job’s complexity, the mechanic’s expertise, and local labor rates contribute to the final bill.

The more intricate the engine design or, the more specialized the skills required, the higher the labor costs will likely be. On average, labor rates can range from $50 to $150 per hour.

Parts Costs

The cost of the rod bearings themselves is another factor that affects the total expense. The make and model of the vehicle, as well as the quality of the bearings chosen, can impact the price; on average, the cost of parts ranges from $20 to $3,000.

While it may be tempting to opt for lower-cost bearings, it is essential to consider their quality. Cheaper bearings may have a shorter lifespan and potentially lead to engine issues in the future. Investing in higher-quality bearings, albeit with a higher price tag, can offer greater durability and peace of mind.

Vehicle Make and Model

The make and model of the vehicle being serviced can significantly influence the cost of rod bearing replacement. Some vehicles, particularly high-performance or luxury models, have complex engine designs that require more time and specialized knowledge to access and replace the rod bearings.

Consequently, the cost for these vehicles tends to be higher compared to vehicles with simpler engine designs that are easier to work on. Below is a table that gives you an idea of rod bearing and labor costs for different vehicle make and models.

| Vehicle | Rod Bearing Cost | Labor Cost |

| Hyundai Sonata | $37.99-$455.88 | $1400-$3290 |

| Ford Mustang | $7.29-$97.99 | $1910-$2740 |

| BMW M5 | $3.99-$458.99 | $1900-$3780 |

Other Factors To Consider

While labor costs, parts costs, and the vehicle’s make and model are the primary factors affecting the cost of replacing rod bearings, there are a few additional considerations. These include the location and reputation of the service provider, any additional fees or taxes, and the warranty coverage associated with the replacement.

Market conditions and pricing fluctuations can also impact rod-bearing replacement costs. Obtaining and comparing multiple quotes is recommended to ensure you receive a fair and competitive price.

Conclusion

When considering the cost of replacing rod bearings, it is essential to consider various factors influencing the overall expense. Labor costs, parts costs, and the complexity of the vehicle’s engine design all play a significant role.

While labor rates can vary based on location and expertise, it is essential to choose high-quality bearings to ensure long-lasting performance. Furthermore, the make and model of the vehicle may impact the overall cost due to the intricacies involved in accessing and replacing the rod bearings.

To get an accurate estimate for your specific vehicle, it is advisable to consult with a trusted mechanic or service center. They can assess your vehicle’s needs and provide a more precise cost breakdown.

Remember that investing in timely rod bearing replacement is essential to maintain the health and reliability of your engine in the long run.