Grease with dielectric properties helps to avoid electrical arcing. Many have pondered the question of what distinguishes dielectric grease from other kind of grease. Is silicone grease the same as dielectric grease? Do you know why dielectric grease is useful? Some of the things that may be bothering you are these inquiries.

How can I define dielectric grease?

To keep electrical connections from rusting or locking up, use dielectric grease, a silicone-based substance. Does dielectric grease conduct electricity? It is a non-conductive grease that is applied to many electrical components, thus the answer is simple. Commonplace examples include spark plugs, battery terminals, and connectors coated with dielectric oil.

If you apply it to electrical connections, it will prevent moisture and other pollutants from corroding and rusting the joints.

The basic function of dielectric grease is to keep two connectors in touch while blocking the flow of electricity between them.

As a result, your electrical connections are stable and trustworthy, and the life of your electrical components is extended. Grease like this also shields them from the damaging effects of weather extremes, humidity, dust, and heat.

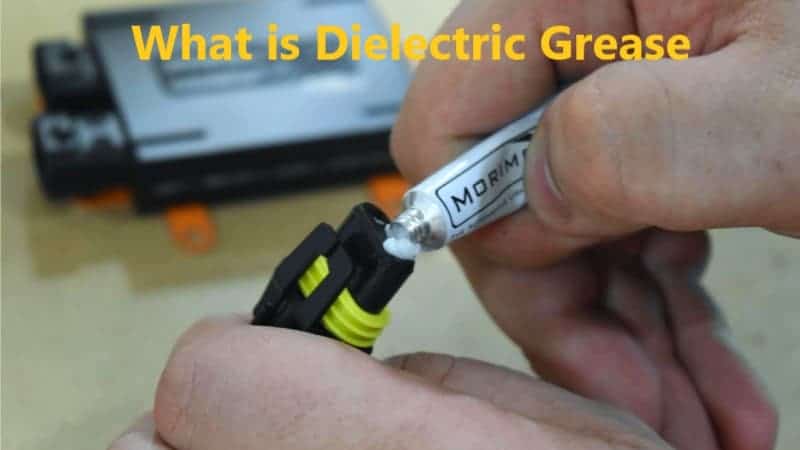

You can buy dielectric grease in jars or spray tubes with a thick viscosity for rapid application. For easy application, use either your fingers or an applicator brush.

For electrical connections, how does one apply dielectric grease? Be careful not to use too much at once, since this can prevent the connection from working at its best.

Various Uses for Dielectric Grease

Among the numerous uses for dielectric grease are high-energy ignition systems, bulb sockets, electrical connectors for trailers, headlights, battery terminals, ignition coils, and spark plug boots. The terminals of batteries are coated with this silicone-based grease so that they do not fuse or corrode.

The use of dielectric grease in a high-energy ignition system serves to seal off any potential voltage leaks. Additionally, it is compatible with a wide variety of connections and terminals, including spades, rings, heat shrink terminals, and butt connectors.

Electrical connectors, particularly those with rubber gaskets, are frequently coated with dielectric grease. The rubber components of the connector are sealed and kept from moving about by this non-conductive lubricant. You can get to places your fingers can’t reach with the help of dielectric grease spray.

This grease has many uses, one of which is in high-voltage connections and spark plugs. Spark wires with dielectric grease applied to their rubber boots are much easier to insert into ceramic insulators. The rubber boot won’t get stuck in the ceramic because it seals it. Because of its great temperature resistance, dielectric grease is ideal for use with spark plugs.

Gaskets of multi-pin connectors and rubber mating surfaces in truck and automobile engines are two other excellent places to apply dielectric grease. Its dual purpose in this context is to lubricate and seal the non-conductive mating surfaces of the connector. Having said that, the connector’s actual electrically conducting contacts should not be greased.

The Basics of Using Dielectric Grease

A thickening is added to silicone oil to make dielectric grease. It can withstand water and fire. You should find out if dielectric grease is an insulator before you use it. To prevent components like LEDs and transistors from overheating, electrical circuits often make use of thermal grease, a type of thermal paste. Inflate the dielectric grease onto the exterior or body of the electrical component.

Be careful the grease doesn’t get into the way of any electrical currents or connections. This occurs because the insulating properties of the grease cause currents to be disrupted. Consequently, dielectric grease should be applied on electrical component surfaces where currents are not flowing.

To begin tuning up a diesel or gasoline engine with dielectric grease, put a small amount on the rubber boot end of a spark plug wire and spread it out to cover the inside lip. As a result, the engine block won’t be able to leak high-voltage electricity to the boot. Putting the boot on top of the ceramic insulator is also made easier by this. It protects the spark plug connection from dirt and water by creating a watertight seal around it.

Additionally, dielectric grease can be applied to the gaskets of pin connectors, which are commonly seen in RVs and boats. Distribute a little amount of dielectric grease onto the gasket, ensuring that it coats both sides if at all feasible. Doing this before inserting the gasket into the connector is recommended.

Conclusion

You should now be able to describe dielectric grease and go over its benefits and drawbacks. As a lubricant and sealant, dielectric grease is second to none. It adds insulation, keeps electrical contacts from arcing, and makes sure they last a long time.

Never use this grease on anything that could conduct electricity; it will prevent current from flowing between electrical connections. Applications involving motors, electrical circuits, and dielectric grease are excellent. Grease with a high melting point is ideal for uses involving elevated temperatures.