Vehicle sensors are fundamental parts of any automobile. To control certain processes or identify issues with various systems, they are useful. Imagine them as receptors. The internal combustion engine would not function properly without the mass airflow sensor.

Given the importance of this vehicle sensor, many are curious about its operation. If you’re worried about the same thing, you’ve come to the correct spot since we’ll be discussing its operation and the telltale symptoms of a malfunctioning mass airflow sensor.

The Basic Concept of a Mass Airflow Sensor

To get a good idea of how it works, have a look at the mass airflow sensor schematic. You should be aware that two main varieties of mass airflow sensors are in use today. Mass airflow sensors come in two varieties: vane and hot wire. In their own unique methods, they communicate with the vehicle’s central processing unit.

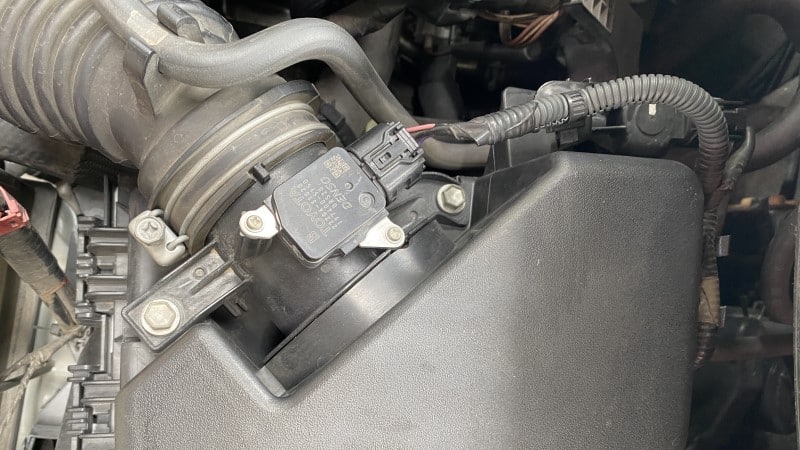

The mass airflow sensor, where is it located? This sensor is often situated in the area between the intake manifold and engine’s air filter. Its placement here makes it an obstruction in the airflow path leading to the combustion chamber.

The Principle of Operation of the Vane Mass Airflow Sensor

Resuming our examination of the working principle, we will begin by examining the vane mass airflow sensor. A potentiometer is linked to a vane that is held in the air stream by a spring. The pressure of the spring will cause the vane to rotate as incoming air forces it to do so.

The carbon track is connected to the power supply unit at one end of the track, and when the vane travels, the slider of the potentiometer pushes along it. Depending on the intensity of the vane’s motion, the signal’s movement is altered by adjusting the slider.

How a Hot Wire Mass Airflow Calibration Works

These days, you won’t find a vehicle without this sort of sensor. A constant temperature is the underlying principle. A wire on this sensor is sticking out into the airflow. A wire composed of platinum and other materials with a comparable conductivity level is heated electrically. The air temperature close to this wire is measured by a temperature sensor that is located adjacent to it.

Imagine the car sitting at a stoplight to get a feel for how it works. A minimal electric current is required to heat the wire because there is little airflow surrounding it. More air can enter the intake manifold as the accelerator is pressed down. The temperature close to the wire will be lowered in relation to the air intake.

Warning Signs of a Defective Mass Airflow Sensor

If your mass airflow sensor is malfunctioning, how can you tell? Some of the signs that this engine part might be about to give out are these.

- While stalling and struggling to get power

- The engine throws a code.

- Low MPG

- High Emissions from Vehicle Emissions

Mass Airflow Sensor Testing Procedures

You need to test the mass airflow sensor to see if it’s functioning properly. It is possible to test this component’s functionality using a number of diagnostic tools. Below this, you will find a selection of them.

How to Check Mass Airflow Sensor Without Using a Multimeter

Variables like as voltage, resistance, and current can be measured using a multimeter. You can’t do without this tool. Having said that, there are workarounds that can be implemented to assess the mass airflow sensor’s health in its absence.

To begin troubleshooting idling issues, put the vehicle in park or neutral and press the parking brake. Next, open the hood and let the engine idle for a while. Tweak the mass airflow sensor gently with a tool like a screwdriver. The sensor is malfunctioning if the engine suddenly stops while running or if the idling behaviour changes.

Disconnecting the mass airflow (MAF) sensor, applying the brakes, and shifting into park should help get the engine started if it won’t start otherwise. Get the motor running. A broken sensor requires replacement if the engine starts easily or idles better.

Use of a Multimeter for Mass Airflow Sensor Testing

The digital multimeter is the tool to utilize for precise measurements. You may use it to check for various variables, which is an outstanding feature of this gadget. Verifying its voltage is a good place to start. Here, you should turn off the ignition. After that, you connect the multimeter’s positive (+) lead to the red lead of the meter and the ground (-) lead to the black lead.

With the gearshift in the parking position, apply the handbrake. Let the engine start and then let it idle. The ideal reading to start the engine is between half a volt and seven volts.

Tap the sensor gently with the handle of a screwdriver or any other tool you have on hand. Assuming there is no variation in the readings, the sensor is functioning admirably. Bad electrical connections are indicated by fluctuations.

Conducting Hot Wire Testing

The hot wire can still be your primary focus while testing the mass airflow sensor. Sometimes the problem is a broken hot wire, so make sure to check its condition. To test the MAF sensor without the key in the ignition, turn it off.

You need to make sure the multimeter is set to Ohms before you attach the leads. A broken hot wire will cause endless resistance.

Conclusion

This article demonstrates the operation of this sensor and is a valuable resource for anyone interested in automotive engineering. If your car’s MAF sensor ever stops working, you’ll be prepared by following it to the second part.