Navigate the silent yet vital world of your car’s heartbeat, the idle control valve, where precision meets performance. Dive into the essence of engine equilibrium and learn how this unsung hero keeps your rides seamlessly smooth. It’s time to tune into the rhythm of your engine’s idle harmony!

The Idle Air Control Valve regulates the idle speed of an engine by controlling the amount of air that enters the intake manifold. It plays a crucial role in maintaining a stable idle and preventing stalling. The Idle Control Valve helps optimize fuel combustion and ensures smooth engine operation by adjusting the airflow.

The Function of the Idle Control Valve

When the throttle plate is closed, such as when the driver releases the accelerator pedal or when the vehicle stands, the engine needs controlled air to maintain a stable idle speed. The idle control valve precisely adjusts the amount of air bypassing the closed throttle plate to ensure a smooth and consistent idle.

The idle control valve receives signals from the engine control unit (ECU) or engine control module (ECM), which continuously monitors engine parameters such as engine speed, coolant temperature, and load. Based on these inputs, the ECU determines the optimal idle speed and sends signals to the idle control valve to adjust the airflow accordingly.

8 Symptoms of a Bad Idle Control Valve

The most common symptoms of issues with idle control valves are choppy inactive and a check engine light on your dashboard. When your IAC valve fails, you may also notice a variable idle speed or a stopping engine at idle.

Here is a more extensive list of symptoms of a faulty or failing idle air control valve (IAC) to watch for:

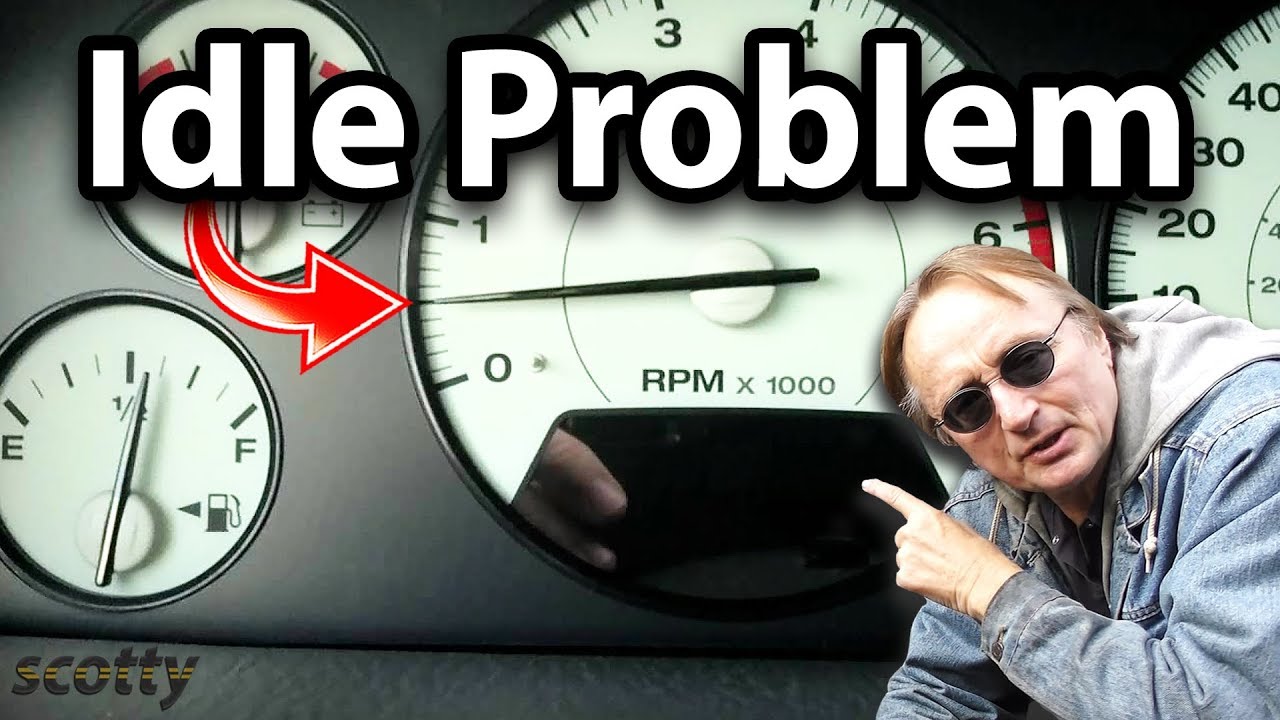

1. Irregular or Rough Idling:

One of the primary signs of a malfunctioning IAC valve is irregular or rough idling. When the valve fails to regulate the airflow properly, the engine may idle at inconsistent RPMs, causing noticeable shaking or vibrating. If you observe your vehicle’s idle speed fluctuating significantly, it could clearly indicate a faulty IAC valve.

2. Stalling at Idle:

A defective IAC valve can result in the engine stalling while idling. When the valve fails to maintain the correct idle speed, the engine may not receive sufficient air, causing it to stall unexpectedly. If your vehicle frequently stalls at a stop or is in neutral, it’s time to inspect the IAC valve.

3. High Idle Speed:

Conversely, an IAC valve that remains open or fails to close properly can lead to an abnormally high idle speed. If you notice your engine revving excessively even when your foot is off the accelerator pedal, it may indicate a malfunctioning IAC valve. This symptom should not be ignored, as prolonged high idle speed can cause engine damage.

4. Difficulty Starting:

A failing IAC valve can make starting your vehicle challenging. When the valve is not functioning correctly, it may restrict the airflow during engine startup, causing extended cranking or even preventing the engine from starting altogether. If you experience repeated difficulties starting your vehicle, inspecting the IAC valve is wise.

5. Poor Fuel Efficiency:

A malfunctioning IAC valve can negatively impact your vehicle’s fuel efficiency. Since the valve controls the air-to-fuel ratio during idle, a faulty valve may result in an excessively rich or lean mixture, leading to decreased mileage. If you notice a sudden drop in fuel efficiency without any apparent reason, a faulty IAC valve could be to blame.

6. Engine Surging:

Engine surging, characterized by sudden increases and decreases in RPMs, is another bad idle air control valve symptom. When the valve fails, it can cause sporadic fluctuations in idle speed, resulting in the engine surging or lurching forward unexpectedly. This erratic behavior can compromise driving safety and should be addressed promptly.

7. Backfiring:

If you hear your engine backfiring or experiencing loud popping noises from the exhaust during idle or deceleration, a malfunctioning IAC valve may be at fault. A faulty valve can cause an imbalanced air-to-fuel ratio, leading to incomplete combustion and subsequent backfiring. Ignoring this symptom can lead to more severe engine damage over time.

8. Check Engine Light:

In many cases, a malfunctioning IAC valve will trigger the vehicle’s onboard diagnostic system, causing the check engine light to illuminate. The system detects irregularities in engine performance and alerts the driver to potential issues. If your check engine light is on, a professional must diagnose your vehicle to identify the underlying cause, which could be a faulty IAC valve.

Causes of Bad Idle Control Valve

A bad idle control valve, also known as an idle air control valve (IACV), can result in various issues with a vehicle’s idle speed and overall performance. Here are some common causes of a malfunctioning or faulty idle control valve:

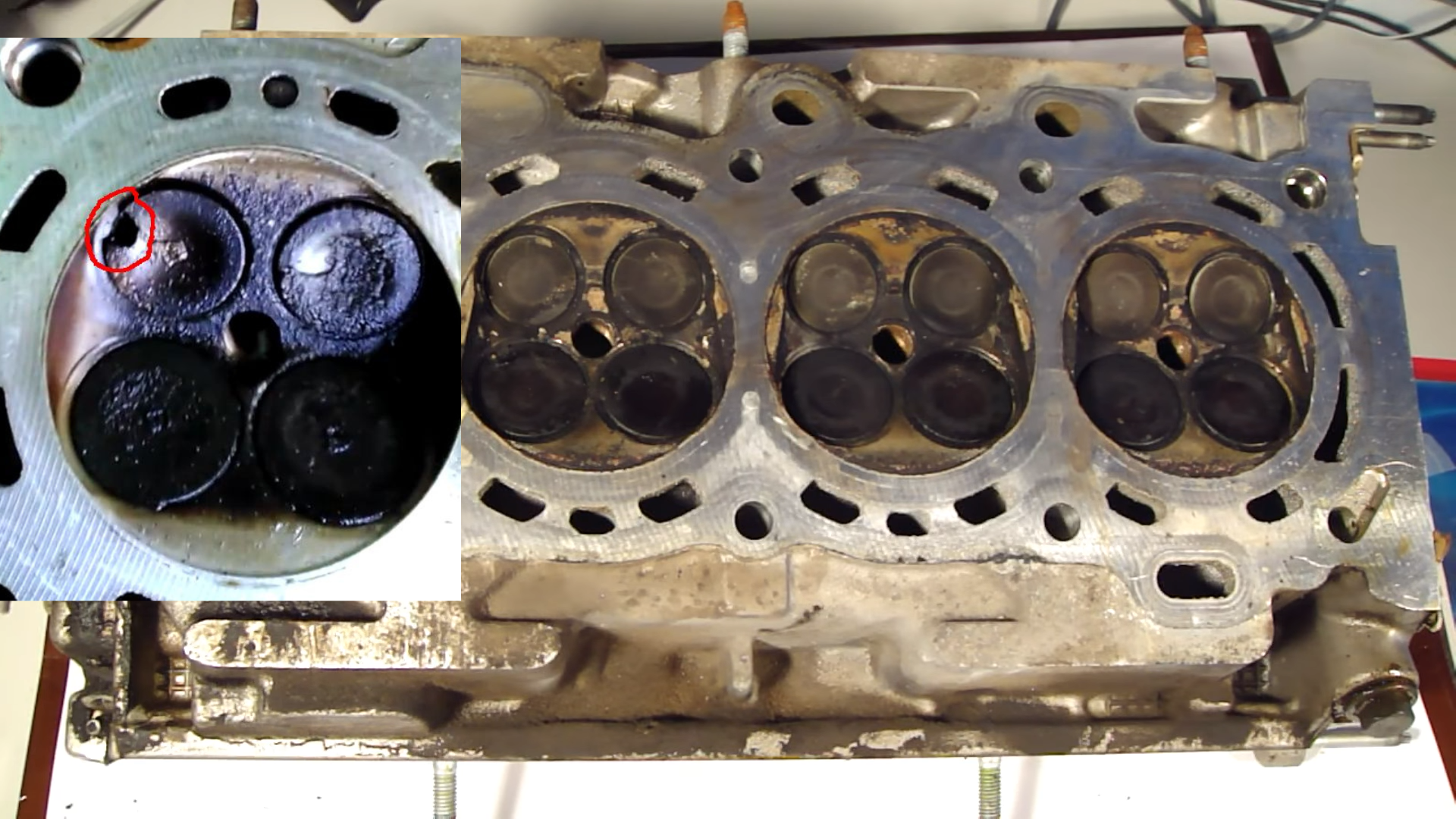

Carbon Buildup

Over time, carbon deposits can accumulate on the idle control valve, causing it to stick or become clogged. This buildup restricts the airflow and disrupts the valve’s proper functioning, resulting in a rough or unstable idle.

Electrical Issues

The idle control valve relies on electrical signals from the engine control unit (ECU) to regulate the airflow. Suppose there are problems with the electrical connections, such as loose or corroded wiring, faulty connectors, or a malfunctioning ECU. In that case, the valve may not receive the correct signals, leading to idle control issues.

Vacuum Leaks

A vacuum leak can affect the proper functioning of the idle control valve. When there is a leak in the vacuum system, unmetered air can enter the intake manifold, causing an imbalance in the air-fuel mixture and disrupting the idle speed control. Faulty vacuum hoses, intake manifold gaskets, or a cracked intake manifold can contribute to vacuum leaks.

Mechanical Wear

Like any mechanical component, the idle control valve can wear out over time due to everyday use. Continuous valve opening and closing can lead to internal wear or damage to the valve mechanism, causing it to malfunction. This can result in erratic idle speed or difficulty maintaining a consistent idle.

How to Fix an Idle Air Control Valve

Fixing an idle air control valve problem doesn’t have to be a daunting task. Here we will provide you with a step-by-step guide on how to fix an idle air control valve, allowing you to restore smooth engine operation and optimize your vehicle’s performance.

Step 1: Gather the necessary tools and materials

Before you begin the repair process, gather the following tools and materials:

- Socket wrench set

- Screwdriver set

- Cleaning solvent or throttle body cleaner

- Clean rags or paper towels

- Replacement gasket (if required)

- Safety glasses and gloves (recommended)

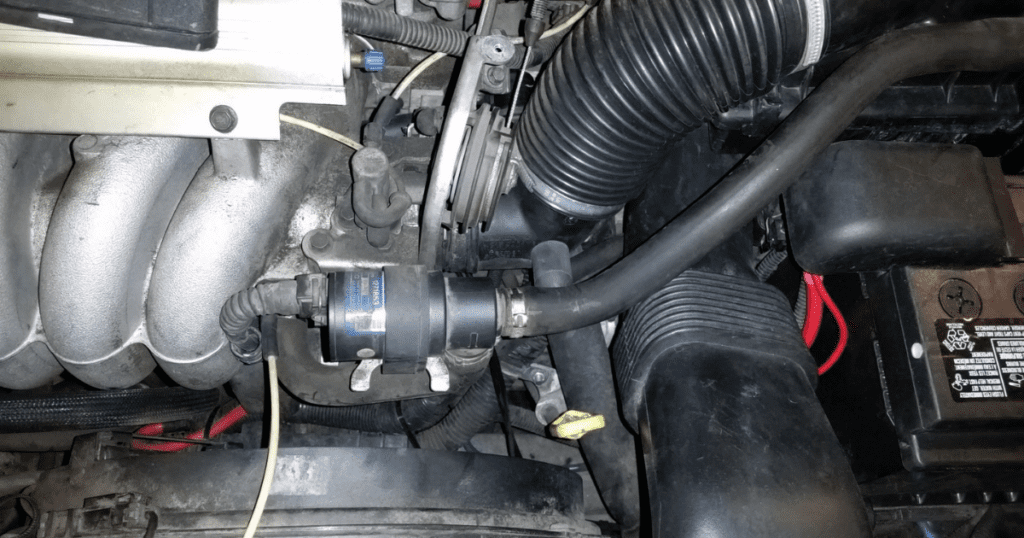

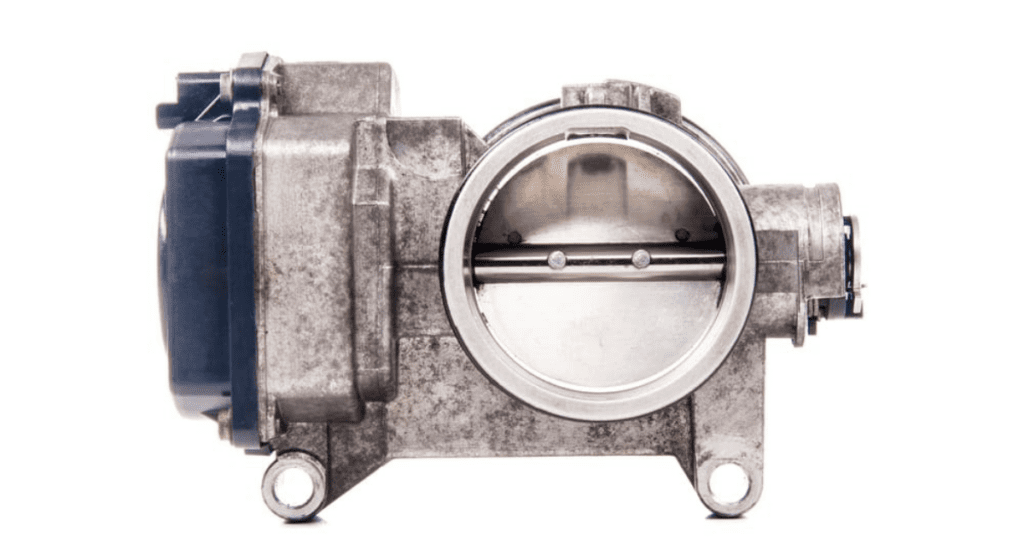

Step 2: Locate the idle air control valve

The IAC valve is typically located on or near the throttle body. Consult your vehicle’s service manual or an online resource to find the specific position of the valve in your car’s engine compartment.

Step 3: Disconnect the battery

Disconnect the negative terminal of the vehicle’s battery to ensure safety and prevent electrical issues. This step will also reset the vehicle’s computer, allowing it to recalibrate after the repair.

Step 4: Remove the idle air control valve

Using a socket wrench or screwdriver, carefully remove the screws or bolts securing the IAC valve to the throttle body. Gently detach any electrical connectors or vacuum hoses connected to the valve. Take note of their positions to facilitate reinstallation.

Step 5: Clean the idle air control valve

Once the valve is removed, inspect it for any signs of dirt, carbon deposits, or clogging. These issues can interfere with its proper functioning. Clean the valve using a suitable cleaning solvent or throttle body cleaner. Follow the manufacturer’s instructions and use a soft brush or rag to remove debris without damaging the delicate components.

Step 6: Inspect and clean the throttle body

While removing the IAC valve, take the opportunity to inspect the throttle body for any buildup of carbon deposits or debris. Use the same cleaning solvent or throttle body cleaner to clean the throttle body’s interior surfaces carefully. This step helps to improve airflow and optimize engine performance.

Step 7: Reinstall the idle air control valve

After ensuring the IAC valve and throttle body are clean and debris-free, reattach the valve to the throttle body. Remind any electrical connectors or vacuum hoses, providing a secure fit. Use the appropriate torque specifications when tightening the screws or bolts.

Step 8: Reconnect the battery and test the repair

Reconnect the negative terminal of the vehicle’s battery. Start the engine and allow it to idle for a few minutes. Observe the engine’s behavior to ensure the idle speed is stable and the previous issues have been resolved. If necessary, make further adjustments or repeat the cleaning process.

Is it possible to drive with a faulty idle air control valve?

You may drive with a faulty idle air control valve. The most crucial concern is whether you should conduct a vehicle with a defective engine. Going with a faulty component, particularly this one, is not recommended. A lousy valve may cause your engine to stall, endangering you and your passengers’ safety.

Understanding that a poor one might cause your car to fail an emissions test is also critical. Park your automobile and consider your next steps to prevent total disaster.

Cost of IAC Valve Replacement

On average, IAC valve repair costs approximately $120 to $500, with components ranging from $45 to over $400, while servicing is just around $70.

Labor expenses are, of course, proportional to the technician’s hourly rate. This work would take no more than an hour to perform, so don’t put a hefty price on it. Certain automobiles are more challenging to work with than others, influencing cost and effort.

Conclusion

The idle control valve is critical for maintaining engine performance and stability at idle. Recognizing the symptoms of a bad idle control valve can help car owners identify issues early on and take necessary corrective measures.

Suppose you notice varying or fluctuating idle speed, rough idle, poor fuel efficiency, stalling or surging, or engine misfires. In that case, you should consult a qualified mechanic to diagnose and resolve the problem promptly. Timely attention to the ICV can prevent further damage to the engine and ensure a smooth and efficient driving experience.