To get your vehicle from A to B, a number of engine parts must cooperate. The mass airflow (MAF) and mass airflow (MAP) sensors are two such engine components that measure the amount of air that enters the engine.

MAF Sensor

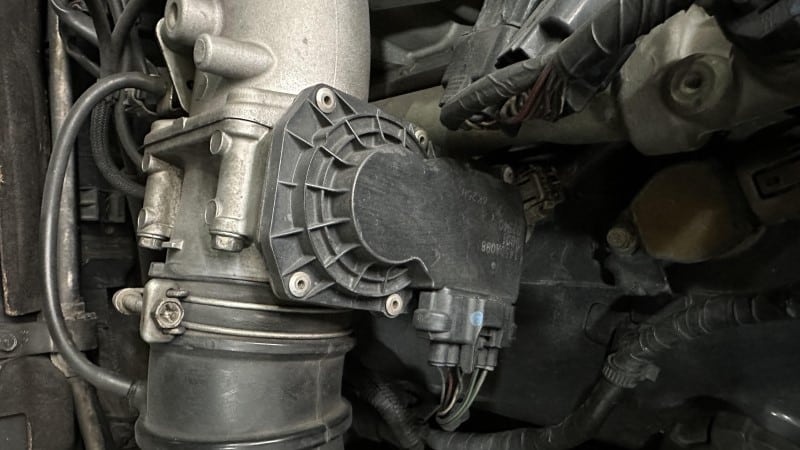

Mass airflow, or MAF for short, is a device that monitors the amount of air entering the engine and reports that data to the powertrain control module (PCM) so that the engine receives the correct amount of fuel. So far as the engine is concerned, the PCM has not sent gasoline.

But it does instruct the fuel injector when and how much fuel to send. Consequently, the MAF sensor needs to be in good working order so it can continuously inform the PCM of the amount of air entering the engine in order for the engine to obtain a balanced air-fuel mixture.

MAP sensor

A manifold absolute pressure, or MAP, is a mathematical concept. This sensor keeps an eye on the vacuum pressure in real time and sends signals to the car’s computer about how to regulate the fuel input to achieve a balanced air-fuel ratio.

Engine misfiring, stalling, rough running, and stuttering can occur if the air-fuel mixture is not adjusted according to the manufacturer’s specifications. Due to the presence of a turbo or supercharger pushing the intake track, MAP sensors are commonly used in supercharged and turbocharged vehicles to monitor the changes in vacuum pressure in real-time.

MAP vs. MAF – What’s the difference?

Although both MAF and MAP sensors monitor the amount of air that enters the engine, the main distinction is in their calculation methods or approaches to determining this air volume. Their positions are another distinguishing feature.

Theoretically, the MAP sensor solely detects the air pressure in the intake manifold, whereas the MAF sensor gauges the overall quantity of air entering the engine. When both of these sensors register a measurement, the vehicle’s computer takes that data and utilizes it to calculate the ideal air-fuel ratio to feed the engine.

The intake manifold air pressure can change with attitude, therefore the onboard computer has to know the manifold absolute pressure to keep up with the track.

You now know that the MAP and MAF sensors perform comparable tasks, but how can you tell if one is malfunctioning?

Low fuel efficiency, a dashboard check engine light, black smoke coming out of the tailpipe, and an underpowered engine are all symptoms of a failed mass airflow or mass airflow sensor. Engine misfiring, reduced power when driving, hard starting, unstable engine running, and other similar symptoms are all possible warning signals.

The only method to find out if the mass air flow or manifold absolute pressure sensor is malfunctioning is to test both of them. It is not uncommon for you to notice those symptoms when the sensors are dusty and require cleaning, rather than when any of the sensors are malfunctioning. Simply utilizing a MAP or MAF cleaner to wipe down the sensors will do the trick in this situation.

Conclusion

Important sensors for regulating airflow into the combustion chamber include mass airflow (MAF) and mass airflow (MAP). The electronic control unit (ECU) receives readings from these sensors and uses them to calculate the ideal air-fuel ratio to inject into the engine.

In contrast to the MAP sensor, which measures air pressure in the intake manifold, the MAF sensor detects the amount of air that enters the engine.