Having a wheel fall off your car while you’re driving fast is one of the scariest things that can happen to you as a driver, whether you’re speeding down the back straight of your local race track or trying to get home in three lanes of rush hour traffic.

The first step is to find the right torque for the lug nuts and lug bolts. Most owner’s manuals have this information. You must use a torque wrench to make sure you are tightening wheel nuts and bolts with the right amount of force. Even though you don’t need a torque wrench to change a flat tire in an emergency, you will want to use one at some point to loosen and re-torque the nuts or bolts on the wheel.

What is Lug Nut Torque?

Car wheel torque or lugnut torque is the tightness of the lug nuts. This tightness is measured in an amount called foot-pounds. The foot-pounds are related to the amount of weight required to move an object a certain distance. Depending on your car’s lugnut tightness, it can be set as high as 90 pounds or lower than 30 pounds.

How Do Lug Nuts Work?

When torqued to the factory-recommended level, lug nuts are made to “stretch” a certain amount. Because of this stretch, the nuts can connect to the threads on the lug in a strong way. If this connection isn’t tight enough, the bolt doesn’t stretch, and the connection is “loose,” so the lug can move and vibrate.

If it is over-torqued, the bolt will stretch to the point where its tensile properties are weakened. This makes it more likely to shear, crack, or otherwise violently separate from the lug.

Types of Lug Nuts

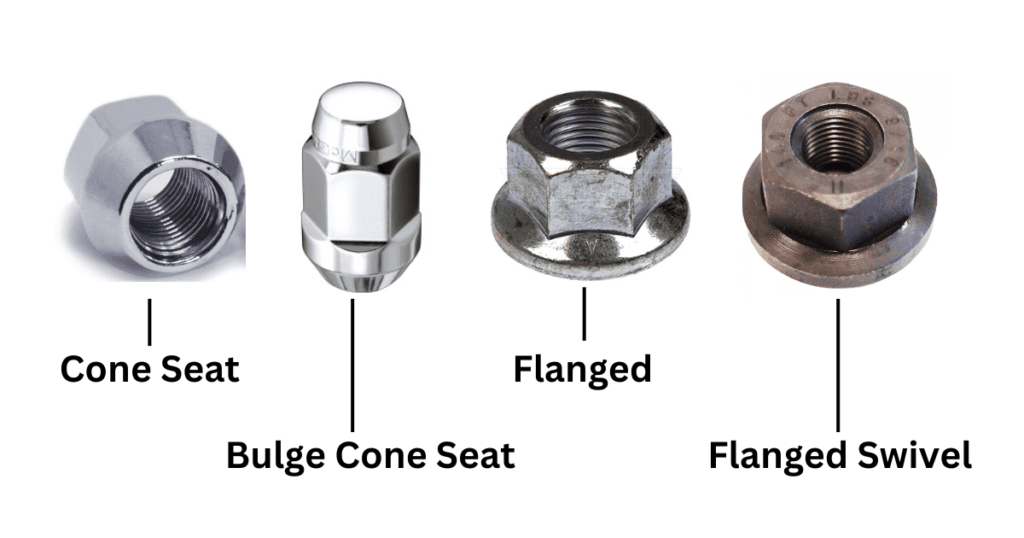

These four types of lug nuts are the most common:

- Cone seat

- Bulge cone seat

- Flanged

- Flanged Swivel

How to Select and Install the Right Lug Nuts for your Wheels?

Learn how to select the right lug nuts for your wheels in 4 easy steps;

- Seat Type

- Thread Size and Pitch

- Wrenching Type

- Appearance

Seat Type

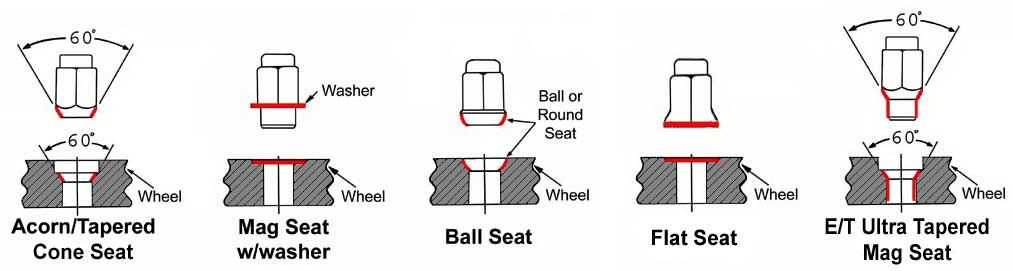

There are different kinds of seats for lug nuts. Knowing the difference is important for the application. Shank or mag seat lug nuts have a flat seat and usually have a washer between the lug nut and the wheel. You have to order these lug nuts based on the size of the shank and how long it needs to be for your wheels.

Make sure you don’t order a shank diameter that is smaller than what your wheels need. If you do, the assembly will not be round or balanced.

The first step in choosing the right lug nuts for your car or truck is to find out what kind of lug nut seat your wheels need. A 60-degree included angle tapered seat lug nut is a very common type of lug nut used in cars. Circle track racing wheels are the only ones that have tapered seat lug nuts at 45 degrees.

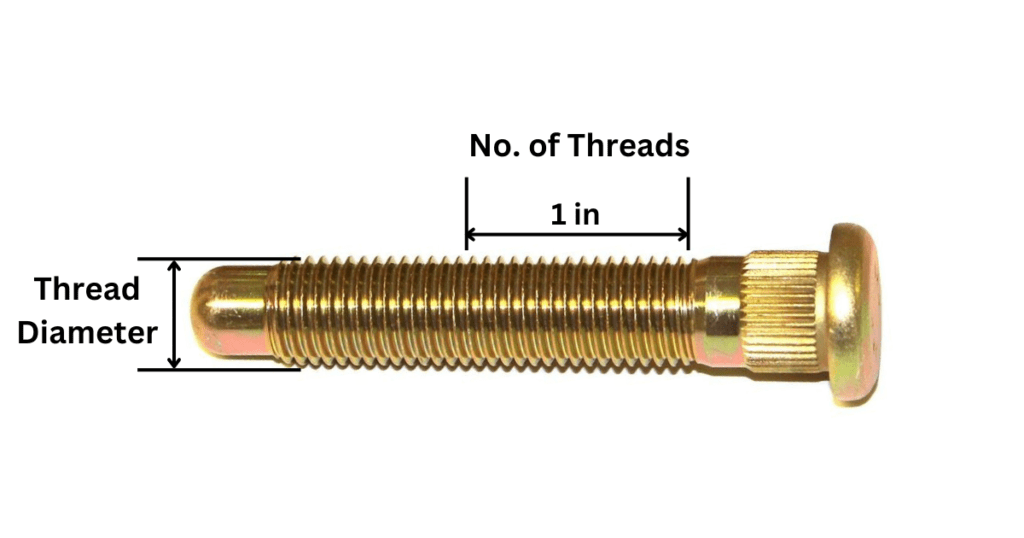

Thread Size and Pitch

To figure out what kind of lug nut thread your car needs, you must first measure the thread size. To do this, measure the outside diameter of the threads on your car’s wheel studs. 7/16″, 1/2″, 9/16″, and 5/8″ are the most common thread diameters for lug nuts in SAE sizes. The diameters of most metric threads are 12 mm and 14 mm.

To find the thread pitch on SAE threads, you need to count the number of threads in a one-inch section of the stud. The most common SAE thread sizes are 7/16″-20, 1/2″-20, 9/16″-18, 5/8″-18, and 5/8″-11. These sizes have 11, 18, or 20 threads per inch.

To figure out the thread pitch on Metric threads, you need to count the number of threads in a 1 mm long section of the stud. 1.25 and 1.50 threads per mm are the most common thread pitches for Metric threads. This means that the most common thread sizes are 12 mm x 1.25, 12 mm x 1.50, and 14 mm x 1.50.

Wrenching Type

Hex lug nuts are the most common by a long shot. Hex lug nuts are the most common because you can use sockets or wrenches to put them on or take them off. When the car needs service or repair, any mechanic or tire shop can take the wheels off or put them back on. When you use hex lug nuts, however, your wheels are more likely to be stolen.

You can use spline drive lug nuts to change the look or match the style of your wheels. One spline drive lug nut per wheel can also be used to keep the car from being stolen. These are called “wheel locks.” To put these lug nuts on and take them off, you will need a very specific socket. In some kits, the spline drive socket is included.

Hex key lug nuts have a smooth look on the outside and are usually used on wheels with a very small hole for the lug nut to fit into. To put these lug nuts on or take them off, you need a hex key. One good thing about this lug nut is that it won’t damage the finish on the outside of the lug nuts when you put them on or take them off.

Appearance

Acorn lug nuts are used on all kinds of vehicles where the look of being capped off and not having a stud in the middle is desired. This gives them a very clean look, making them great for hot rods, muscle cars, show cars, and cars that you drive every day.

When you buy lug nuts, you should also think about the finish or color. Many open-end lug nuts are zinc-plated to keep them from rusting, but they don’t have the shine that is sometimes desired. Chrome plating gives a shiny look that can be used for many different things. There are also different black lug nut options to make the look even more unique to your wheels.

Lug Nuts Specifications

Torque the lug nuts in two steps, starting with 40 ft/lbs of torque for the first step to get the wheel in place. Then, for the final torque, look at the chart below. It shows how much torque you should use based on the size of the threads on your lug nuts. Make sure to follow the torque order shown below for your particular number of lugs.

| Lug nut thread | Torque ft/lb | Minimum no. of turns |

| 12 mm | 70-80 | 6.5 |

| 14 mm | 85-90 | 7.5 |

| 7/16 in | 70-80 | 9 |

| 1/2 in | 75-85 | 8 |

| 9/16 in | 135-145 | 8 |

How to Torque Your Car Wheels Properly

Installing lug nuts in an alternating pattern, called a “star pattern,” makes sure that the weight is spread evenly over the wheel mounting surface. You should use a calibrated torque wrench to tighten them. You can also use a socket wrench or an impact wrench, but the final tightening should always be done with a torque wrench.

Depending on the vehicle and wheel type, torque specifications are different. Manufacturers give recommended torque values that should always be used when installing. After installing, you should re-torque the wheels after driving the vehicle for 50 km.

What Happens if the Wheels are not Torqued Properly?

If lug nuts aren’t tightened enough, it can lead to;

- Wheel hub damage

- Damage to lug nut seating surface

- Warped brake rotors

This video demonstrates how easily you can torque your lug nuts.

FAQs

Can I tighten the nuts on my wheels too much?

Yes, you can make your car’s wheel nuts too tight. This can damage the wheel or the threads on the nuts, and it can also make it harder to take the nuts off in the future. To keep from overtightening your wheel nuts, it’s important to pay close attention to the manufacturer’s torque recommendations.

How often should new wheels be torqued?

It’s important to torque new wheels so that they fit the car. As a general rule, you should tighten your new wheels after 50 or 100 miles. If you drive in bad weather or on rough roads, like when it’s raining hard, you should check the torque more often.

What happens if I overtighten lug nuts?

When you overtighten, the wheel studs get stretched. The wheel is attached to these metal posts or bolts. Because of this strain, the stud might break. This crack could cause damage to the tires. It could also break the bolts. There is even a chance that the brake rotors will bend.

Why is the right torque important?

The right torque helps your car’s wheel to work optimally. It makes sure that your car’s wheels are properly attached, so you can safely speed up, turn, and stop. Without the right amount of torque, the tires on your car might not work right or might even get damaged.

Final Words

It only takes a few minutes per wheel to make sure the torque is right. Those few minutes can save you a lot of money if you avoid an accident that could cause you to lose control of your car. Your car might not run as well or be as safe on the road if the wheel torque isn’t right. Hopefully, you have gained a thorough understanding of lug nut torque after reading this article.