Most workshop power tools feature electric motors. Their main purpose is to convert electricity to mechanical force. This is found in power drills, electric saws, and car lifts. Brushless vs. brushed electric motors are our main focus.

Understanding the differences between the two types is key to learning how they work and their efficiency. Check out each motor to find which works best in different conditions.

Brushed Motors

First, we discuss brushed motors. They are powered by direct current and are vital to electrical-mechanical forces. This motor is distinguished by its brush. It transfers wire current to rotating elements. Due to its resistance, the brush is largely graphite.

How Brushed DC Motors Work

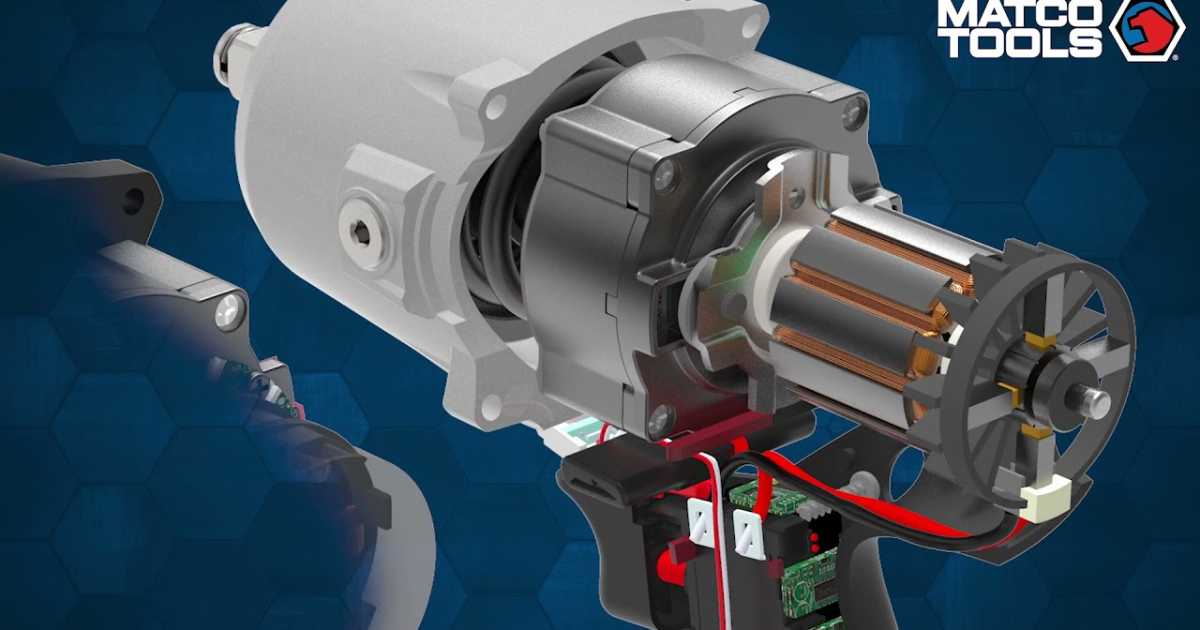

Regular pieces include the armature, permanent magnets, commutator rings, and brushes. When electric current is applied, the armature’s coils have electromagnetic properties. It retains the shaft.

Coils around steel or aluminum plates in the armature sustain shaft torque as it spins. The armature has commutator rings. They rotate with the armature and brushes. Stators—immovable parts—are magnets. They form a ring around the armature with opposite charges.

The brushes conduct electricity from the cables to the armature coils. This arrangement becomes an electromagnet with current. Power attracts the coil to the opposite-charged magnet. The current will reverse polarity at the opposite brush, making the coil repel its magnet and attract the other.

This cascade of reactions rotates the coil-over structure. A positively charged coil goes toward a negatively charged permanent magnet and vice versa.

Brushless Motors

Motor controllers replace brush and commutator rings. Due to efficiency, brushless motors are preferred.

How Brushless DC Motors Work

Brushed and brushless DC motors act oppositely. Relay wire current goes to coils via the controller. Direct current pulse amplitude and phase are controlled. Controls motor torque and speed.

Three-phased coils become electromagnets when current-powered. Coils attract or repel permanent magnet rotors. It sometimes mixes both, improving efficiency.

The sensor is another important brushless motor part. It sends the controller rotor location. The controller then energizes coils for precise timing and position. This is key for motion control.

Brushed DC Electric Motor Benefits

The basic nature of brushed electric motors makes constriction cheap. It makes buying them affordable. Another plus of the brushed variant is easy rebuilding. It lasts longer and performs better after rebuilding.

Disadvantages

The main drawback of brushed motors is maintenance. The brushes may wear out quickly, making it frantic and expensive. The brushes must be replaced for efficiency. It is less efficient than brushless. We consider speed, acceleration, and torque for efficiency. Also noisy is the brushed DC motor. It generates too much heat when running.

Advantages of Brushless Motors

Many people are switching to brushless electric motors because of their benefits. Its best feature is efficiency. Fast, it works perfectly at different speeds and weight-load restrictions. Without brushes, maintenance is easy.

Additionally, brushless electric motors are quiet. Thus, working with them is easy. This motor manages heat well. Do not overheat when running. Additionally, they are light, making motor-powered machines comfortable to use.

Cons

Brushless electric motors are expensive. They’re expensive, but their qualities justify it. The permanent magnet may also demagnetize owing to temperature variations. It needs attention to retain magnetic characteristics.

Brushless vs. Brushed Drill

A mechanic’s toolset includes a fixture hole drill. Compare Ryobi brushed vs. brushless drills to choose a drill. Brushed drills work well and cheaply. A cheap brushed DC motor drill is good.

The best service comes from Ryobi professional brushless drills. Handling is easy due to their little weight. Speed and torque make the motor useful. Its soft sound won’t irritate you. Although pricey, brushless electric motor drills are recommended.

Performance: Brushed vs. Brushless

Brushed or brushless RC crawler motors will determine performance. Brushed RC motors are common. Reliable and cheap by RC standards. They also provide outstanding throttle control for slow-speed rock climbing or weight towing in rough terrain.

Many RCers used brushless motors. Built to last, this DC motor is quick, torquey, and easy to maintain. Which motor you use for your RC depends on its use.

The Difference Between Brushless and Brushed?

Brushless and brushed motors turn electricity into mechanical power. But their structures differ. Commutator rings and brushes carry electricity between the wire and armature. Around the armature are permanent magnets. Electric current and magnetic forces make the armature an electromagnet.

Motors without brushes are brushless. A regulation controller is used instead. Around the permanent magnet armature are wire coils. Electromagnets created by coils of electricity rotate the magnetic rotor.